Filter precision : 0.5-800μm

Cartridge : candle filter cartridge

Material: S.S 304, 316L, Carbon steel

Warranty of core components :1 Year

Filter area :1-60m2

Design temperature :1-200°C

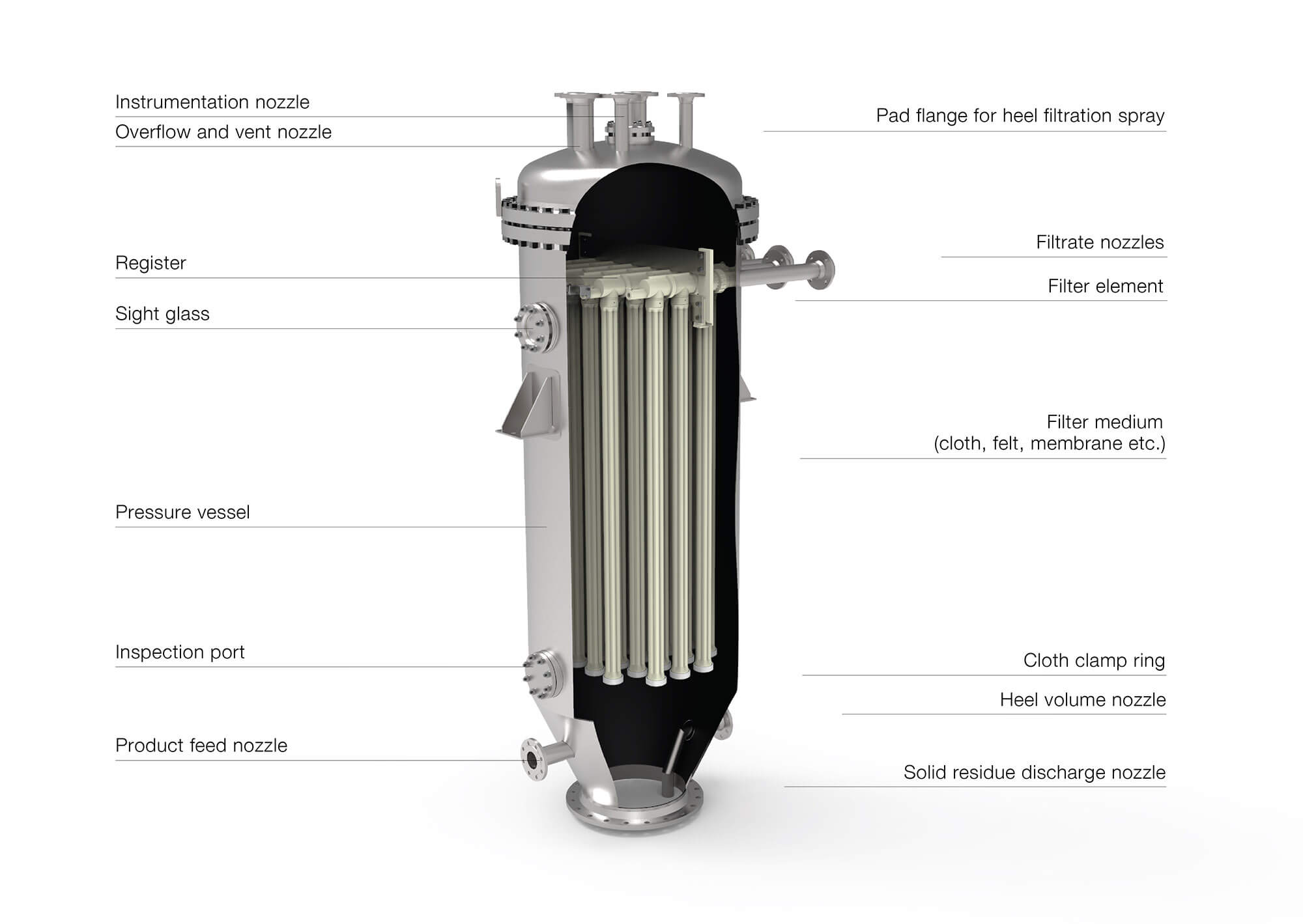

Candle filter is a kind of automatic filter equipment. Candle filter is a filter that uses the filter cartridge as the skeleton. The filter medium are the filter cloth and filter cake layers that covering the filter cartridge, and uses pump pressure to achieve liquid clarification.

Candle filter can choose different filter materials according to the filter medium, filter precision, filter residue viscosity and so on.

High Quality & High Hygiene Standards

| Model | Cartridge QTY | Cartridge Size (mm) |

Filtering Area (m2) |

Capacity (t/h) |

Housing Volume (L) |

Inlet | Cake Discharging Outlet | Total Height (mm) |

| DZZS-1 | 7 | 90*500 | 1 | 2.2 | 140 | DN25 | DN150 | 1902 |

| DZZS-1.5 | 10 | 90*500 | 1.5 | 3.3 | 180 | DN25 | DN200 | 1928 |

| DZZS-2 | 7 | 90*1000 | 2 | 4.4 | 220 | DN32 | DN150 | 2402 |

| DZZS-3 | 10 | 90*1000 | 3 | 6.6 | 280 | DN40 | DN200 | 2428 |

| DZZS-4 | 14 | 90*1000 | 4 | 8.8 | 400 | DN40 | DN200 | 2502 |

| DZZS-6 | 19 | 90*1000 | 6 | 13.2 | 560 | DN50 | DN250 | 2578 |

| DZZS-8 | 24 | 90*1000 | 8 | 18 | 740 | DN65 | DN250 | 2644 |

| DZZS-12 | 40 | 90*1000 | 12 | 26 | 1200 | DN65 | DN300 | 2854 |

| DZZS-18 | 64 | 90*1000 | 18 | 40 | 1800 | DN80 | DN400 | 2904 |

| DZZS-30 | 106 | 90*1000 | 30 | 66 | 3000 | DN100 | DN500 | 3440 |

| DZZS-40 | 140 | 90*1000 | 40 | 88 | 3815 | DN150 | DN500 | 3560 |

| DZZS-60 | 190 | 90*1000 | 60 | 132 | 5700 | DN150 | DN500 | 3700 |

Candle filter is mainly composed of cylinder, filter cartridge, filter cloth, filter aid, PLC control system and other accessories. Other auxiliary equipment includes air compressor, pump, etc. The material of cylinder and filter cartridge is mainly stainless steel (304/316/321), carbon steel, titanium, the material of the filter cloth is mainly PP (polypropylene), PE (polyester), PPS (polyphenylene sulfide), PTFE (polytetrafluoroethylene), nylon fiber, etc. The amount of filter agent added is different according to different processes. The recommended ratio is between 1% and 3%, mainly including activated carbon and diatomaceous earth.

The candle filter is closed and composed of multiple porous filter cartridges (candle filter cartridges), and the filter cartridge is covered with a matching filter cloth. When these solid substances reach a certain thickness, the so-called "filter cake layer" is formed. Because the gap between the particles in the filter cake layer is very small, the escape of particulate impurities in the liquid is blocked, so that the filtrate becomes clear and the filtration effect required for production is achieved, so the candle filter is also called the filter cake layer filter. When the filter cake layer exceeds a certain thickness after normal filtration for a period of time, the rate of filtrate passing through the filter cake layer decreases, and the filtration efficiency becomes poor, and the "filter cake layer" needs to be removed. At this time, the system will perform backflushing according to the signal provided by the pressure sensor. To remove the cake, open the valve at the bottom of the cylinder to discharge slag, and then rebuild a new "filter cake layer" to start a new round of filtration cycle.

Fructose syrup filtration; decarbonization and decolorization filtration of citric acid, malic acid, sulfuric acid, and lactic acid; lycopene filtration; decarbonization and decolorization filtration of monosodium glutamate; yeast, soybean protein precision filtration; various fruit juice precision filtration; soy sauce, vinegar filtration; Precision filtration of alcohol and beverages; Precise filtration of crude oil, edible oil and blended oil.

Filtration in the biopharmaceutical industry; filtration of fermentation broth; filtration of crystals; filtration of mother liquor or suspension; filtration and recovery of catalysts.

Filtration and recovery of pesticide intermediates; filtration of titanium dioxide and black carbon powder in refining waste plastics and waste tires; filtration of biomass oil made from straw; filtration and recovery of PTA mother liquor; filtration of high-purity alumina; filtration of solvent oils such as white oil; polyether desalination filtration of oil sand crude oil; filtration of filter aids (activated carbon, clay, diatomite, perlite, etc.); filtration of amine liquid desulfurization and decarbonization; PTA, PVC powder recovery and filtration; production and filtration of inorganic salts, etc.

Filtration of various types of wastewaters: such as heavy metal wastewater (electroplating wastewater, circuit board production wastewater, hot-dip galvanizing wastewater), battery wastewater, magnetic material wastewater, electrophoresis wastewater, coal mine wastewater, coal stacking wastewater, and fluorine-containing wastewater; chemical production contains wastewater. Filtration of suspended solids wastewater; filtration of grinding liquid for electronic and optical lenses; precision filtration of pigment latex waste paint water; filtration of river water, groundwater, river water, spring water, swimming pool water, and bath water.

Dewaxing, decolorization and fine filtration of industrial oil; filtration of biodiesel, hydraulic oil, waste oil, mixed oil, base oil, diesel oil, kerosene, lubricating oil, transformer oil; dewaxing, decolorization and filtration of vegetable oil and edible oil, etc.