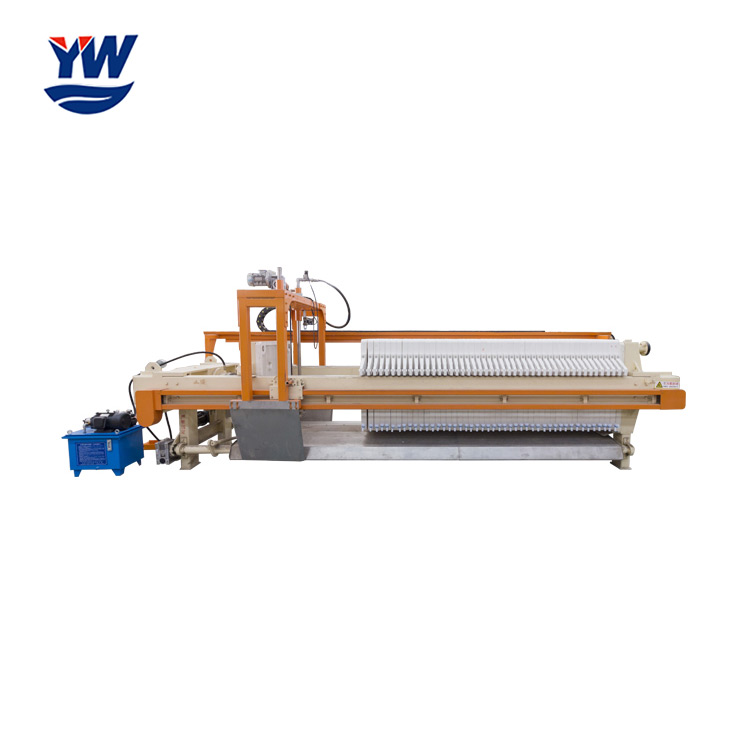

Models : Chamber Filter Press

Filter Plate Size : 1500-2000mm

Control : PLC

Plate Shifting : Automatic hydraulic

Higher Feeding Pressure : 0.6-1.2MPa

Cake Discharging : Automatic

Program-controlled automatic chamber filter press can carry out multiple operations, such as, filter plate pressing, liquid collector plate open/close, filter plate releasing, filter plate withdrawing, cloth washing, with micro chip cotroller, PLC touch screen installed. You can also deal with all the works by remote control of this machine.

With shifter assembled and meanwhile the hydraulic cylinder enhanced, program-controlled automatic chamber/recessed filter press turns to be an energy-efficient filter press, it could discharge more filter cakes as before.

PLC Controller

Remote control interface

Automatic filter cloth washing system

Automatic plate shifting

Automatic drip tray

Automatic hydraulic system

| Model | Filter Area (m²) |

Plate size (mm) |

Cake thickness (mm) |

Filter chamber volume (L) |

Plate QTY (pcs) |

Motor power (KW) |

Dimensions L*W*H(mm) |

| XMZ200/1500−35U | 200 | 1500*1500 | 35 | 2998 | 49 | 7.5 | 6400*2200*1900 |

| XMZ250/1500−35U | 250 | 3594 | 61 | 7225*2200*1900 | |||

| XMZ300/1500−35U | 300 | 4347 | 74 | 8130*2200*1900 | |||

| XMZ350/1500−35U | 350 | 5043 | 86 | 8950*2200*1900 | |||

| XMZ400/1500−35U | 400 | 5796 | 99 | 9880*2200*1900 | |||

| XMZ450/1500−35U | 450 | 6492 | 111 | 10690*2200*1900 | |||

| XMZ500/1500−35U | 500 | 7187 | 123 | 11560*2200*1900 | |||

| XMZ600/2000−40U | 600 | 2000*2000 | 40 | 8926 | 85 | 15 | 11100*3000*2500 |

| XMZ700/2000−40U | 700 | 10380 | 99 | 12200*3000*2500 | |||

| XMZ800/2000−40U | 800 | 11210 | 107 | 13350*3000*2500 | |||

| XMZ900/2000−40U | 900 | 13290 | 127 | 14500*3000*2500 | |||

| XMZ1000/2000−40U | 1000 | 14740 | 141 | 15600*3000*2500 |

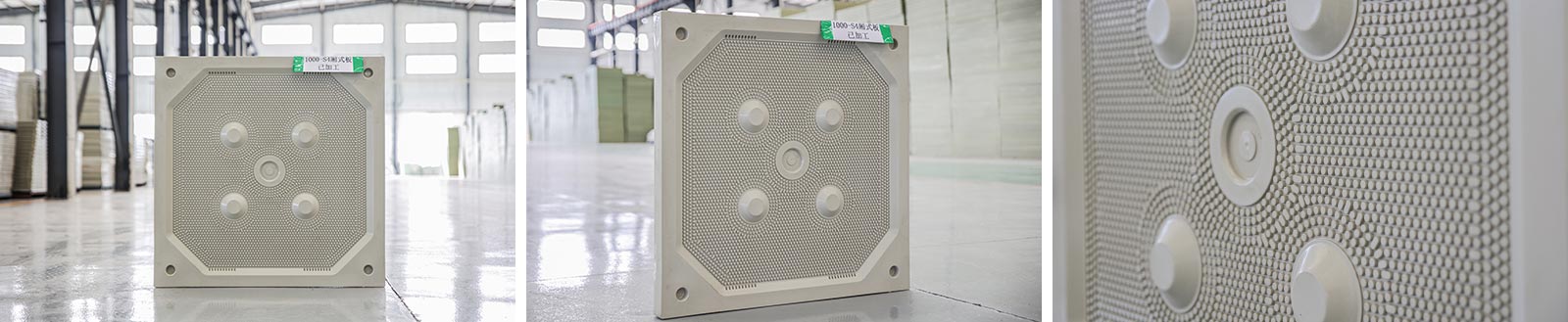

The chamber filter press consists of two recessed filter plates adjacent to each other.

The filter plates have pits and tabs on the surface to support the filter cloth. The filter plates have through-holes in the center and corners and are assembled to form a complete channel for passing suspended liquor, rinse water and drawing out filtrate. The filter plates have handles on both sides and are supported on the crossbeam, which is pressed by a compression device. The filter cloth between the filter plates acts as a seal.

Under the pressure of the feed pump, the material liquid to be filtered is fed into each filter chamber, and the solid-liquid separation is carried out through the filter medium (suitable filter cloths are selected according to different industries). Sludge is formed on the filter cloth until the filter chamber is filled to form a filter cake. The filtrate flows through the filter cloth and along the groove of the filter plate to the lower outlet hole channel and is discharged centrally. After the filtration is completed, the residue on the filter cloth can be rinsed with clean water.

The program-controlled high-pressure chamber filter press is widely used for solid-liquid separation in petrochemical, metallurgical (gold, silver, copper, iron, zinc, rare earth, etc.), petroleum (light oil, glycerin, motor oil, vegetable oil etc.), ceramics (bentonite, active white clay, porcelain clay, etc.) and other industries.

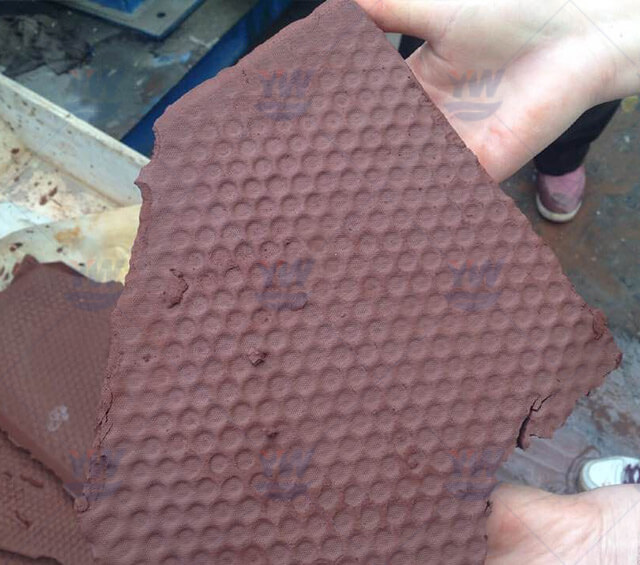

cake of dyestuff

Cake of Sand Wash

Cake of coal Wash

Cake of Hematite

Cake of Cement

Cake of Dyeing Wastewater