Material: Stainless Steel / Carbon Steel / PP

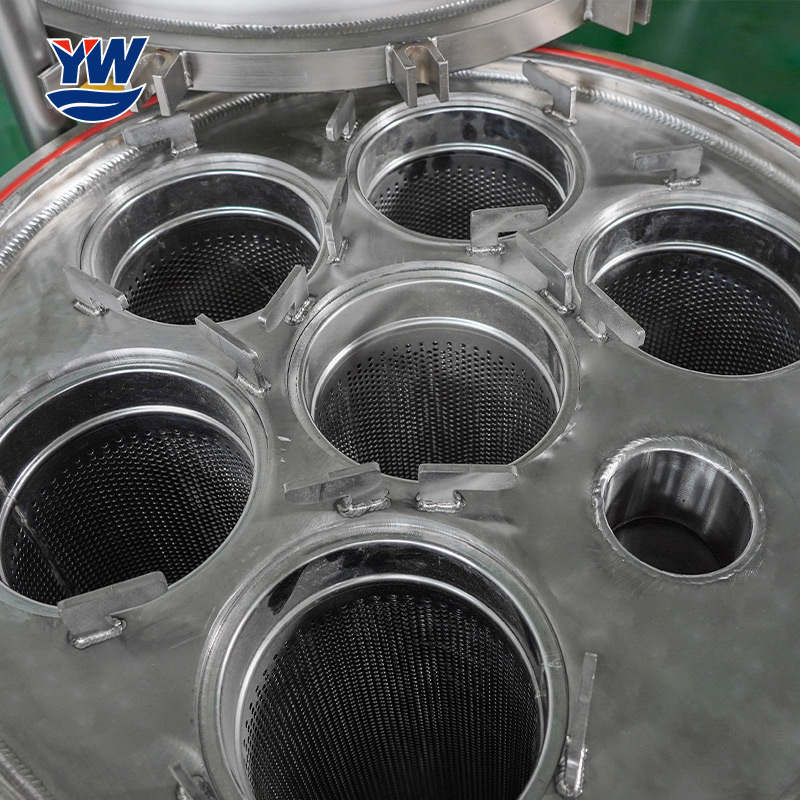

No. of filter bags : 2-24

Filter Area : 1-12m²

Max Flow : 70-840(t/h)

Working Pressure : 0.5Mpa

Filtering Precision : 0.5μm

The bag filter is a multi-purpose filtration equipment with novel structure, small volume, simple and flexible operation, energy saving, high efficiency, airtight work and strong applicability.

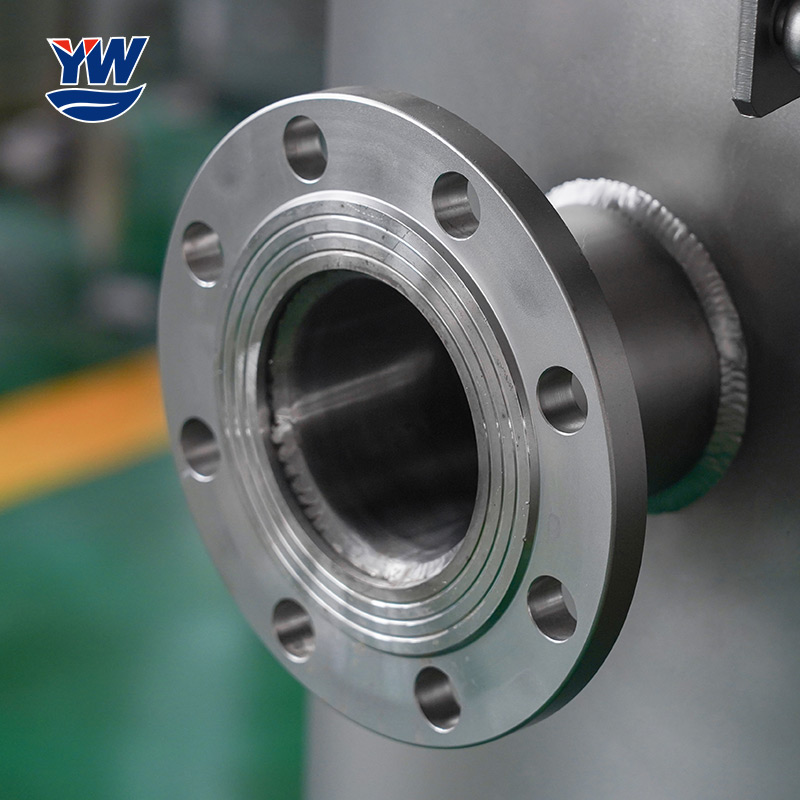

The inside of the bag filter is supported by a metal mesh basket. The liquid flows in from the inlet and flows out from the outlet after being filtered by the filter bag. The impurities are intercepted in the filter bag and can be used continuously after the filter bag is replaced.

Bag filter has the following categories: single bag filter, multi-bag filter, rocker bag filter, high-precision bag filter, etc., the filter filtration precision is in the range of 1-10 microns.

| Models | No. of filter bags | Filtration Area (m²) |

Flow rate (m³/h) |

I/O Connections | Max pressure (Mpa) |

Housing Diameter (mm) |

Total Height (mm) |

Housing Height (mm) |

| DL-2P2S | 2 | 1 | 70 | DN50 | 0.5 | 456 | 1572 | 1144 |

| DL-3P2S | 3 | 1.5 | 105 | DN80 | 0.5 | 508 | 1592 | 1190 |

| DL-4P2S | 4 | 2 | 140 | DN100 | 0.5 | 558 | 1632 | 1244 |

| DL-5P2S | 5 | 2.5 | 175 | DN150 | 0.5 | 608 | 1788 | 1254 |

| DL-6P2S | 6 | 3 | 210 | DN150 | 0.5 | 658 | 1854 | 1300 |

| DL-7P2S | 7 | 3.5 | 215 | DN150 | 0.5 | 710 | 1875 | 1340 |

| DL-8P2S | 8 | 4 | 280 | DN150 | 0.5 | 760 | 1922 | 1404 |

| DL-10P2S | 10 | 5 | 350 | DN200 | 0.5 | 910 | 2004 | 1430 |

| DL-12P2S | 12 | 6 | 420 | DN200 | 0.5 | 962 | 2064 | 1460 |

| DL-14P2S | 14 | 7 | 490 | DN200 | 0.5 | 1012 | 2124 | 1490 |

| DL-16P2S | 16 | 8 | 560 | DN250 | 0.5 | 1112 | 2146 | 1512 |

| DL-18P2S | 18 | 9 | 630 | DN250 | 0.5 | 1162 | 2225 | 1595 |

| DL-20P2S | 20 | 10 | 700 | DN250 | 0.5 | 1212 | 2280 | 1640 |

| DL-22P2S | 22 | 11 | 770 | DN250 | 0.5 | 1366 | 2320 | 1694 |

| DL-24P2S | 24 | 12 | 840 | DN300 | 0.5 | 1416 | 2358 | 1748 |

Bag filter is a pressure type filtering device, which mainly consists of filter cylinder, filter cylinder cover, stainless steel filter bag reinforcing mesh and other main components. The filtrate flows into the filter bag through the side inlet pipe of the filter shell. The filter bag itself is installed in the reinforcing mesh basket. The qualified filtrate can be obtained when the liquid permeates through the filter bag with the required fineness level, and the impurity particles are intercepted by the filter bag. It is very convenient to replace the filter bag. There is basically no material consumption for filtering.