Beer filtration is a very important production process in the beer production process. It is related to the appearance and taste of beer, as well as biological stability and abiotic stability. This ensures that the appearance of the beer will not change at least during the shelf life, thus ensuring the perfect appearance and quality of the beer. In beer that has matured after fermentation, a small amount of coagulated matter such as yeast and protein is suspended in the wine liquid, causing the beer to become turbid during storage. In order to ensure the appearance and taste of the beer, it must be removed through a filtration process.

Main factors affecting beer filtration

The main factors that affect beer filtration include polysaccharides, proteins, yeast and bacteria, and the brewing process.

Polysaccharides

- Raw material varieties and gum content

- Degree of solubility during malt preparation

- Number and molecular weight of polysaccharides

- Agglomerates formed by polysaccharides

Protein

- Protein decomposition and coagulation effects

- Quantity and polarity of condensate

- Protein quantity and molecular weight

- Degree of association of hydrophobic proteins

Yeast and bacteria

- Aggregation performance of yeast

- Autolysis and secretion of yeast

- Contamination and secretions from miscellaneous bacteria

- Sedimentation and separation rate of yeast

Brewing process

- Feeding temperature and saccharification temperature

- Time at high temperature

- Various shear forces in the process

- Brewing temperature and wine storage time

- Solid-liquid separation effect of each process

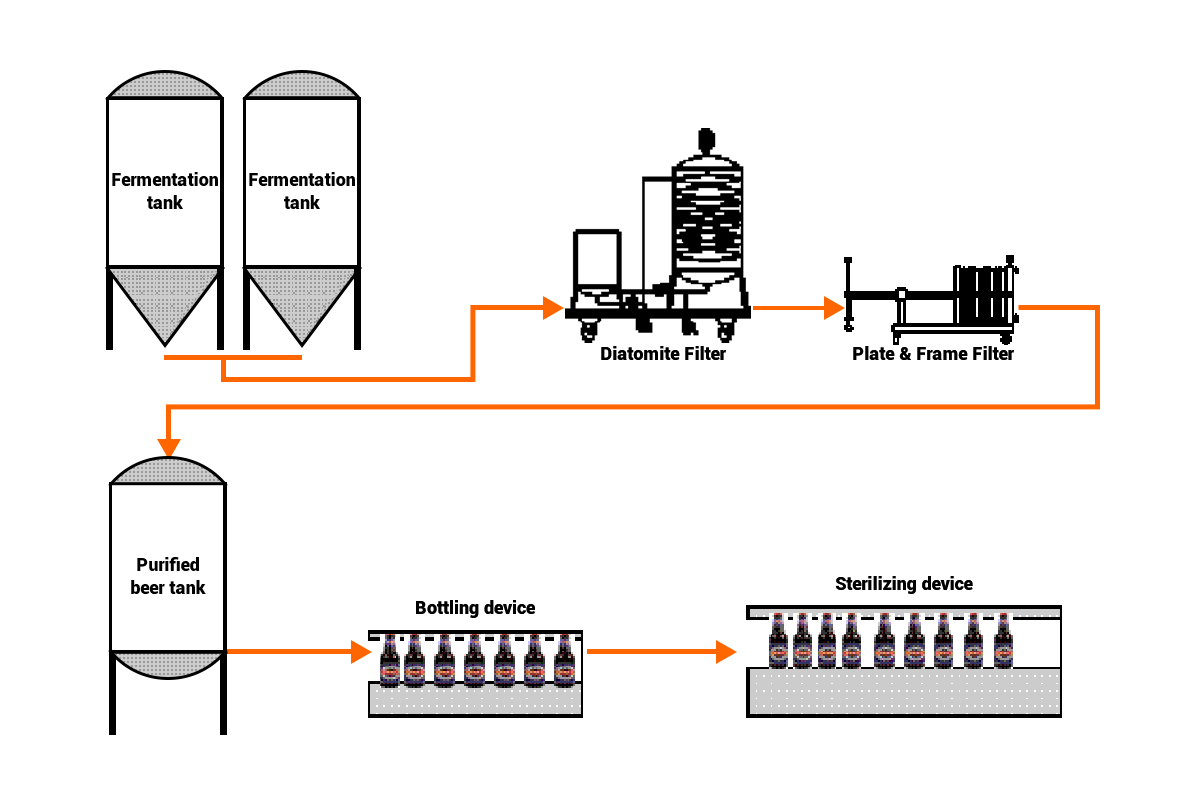

Filtering processes and operations

Filtration Methods

- For beer filtration:

- Cotton cake filter;

- Diatomite filter (coarse filter, commonly used in breweries)

- Cardboard filter (fine filter);

- Dual-flow filter;

- Cross-flow filter (mainly used to replace diatomite filter);

- Sterile filter (mainly used for filtration of pure draft beer)