Models : Belt filter press

Type : Drum concentrated belt filter press

Filter Area : 3-45m³/hr

Dry Solid : 45-675kg/hr

Cake Moisture : 65%-84%

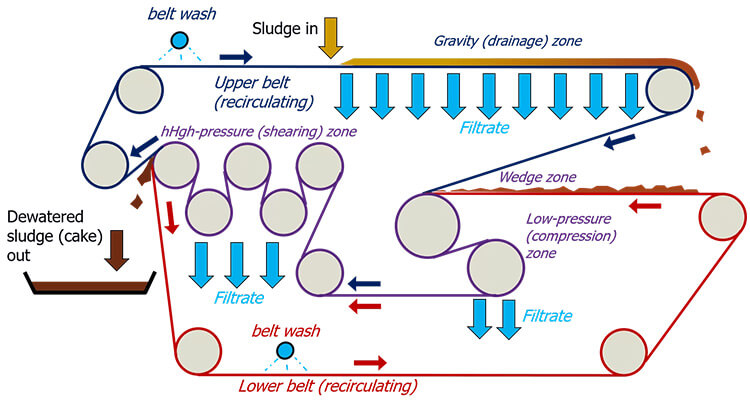

The belt filter press is a continuous operation dewatering machine that separates sludge solids and liquid from the wastewater. Belt filter press are used both municipally and industrially in a range of areas including urban sewage and wastewater treatment, metallurgy and mining, steel plants, coal plants, breweries, dyeing, tanneries, as well as chemical and paper factories.

Compared to other dewatering equipment, such as centrifuges, screw presses, and plate and frame presses, the belt filter press has several advantages.

| Model | Belt Width | Capacity (m³/hr) [ Feed Concentration (Solid content 0.5%-1%) ] |

Dry Solid(kg/hr) | Cake Moisture | Driving Motor | Mixing Power | Gravity concentrator motor |

Size(L*W*H) |

| DNY500 | 500mm | 3-5.2 | 45-78 | 65%-84% | 0.75kw | 0.37kw | 0.37kw | 2600*1050*2175mm |

| DNY750 | 750mm | 4.5-7.5 | 68-113 | 65%-84% | 0.75kw | 0.37kw | 0.37kw | 2600*1300*2175mm |

| DNY1000 | 1000mm | 6-10.5 | 98-158 | 65%-84% | 0.75kw | 0.37kw | 0.37kw | 2600*1550*2270mm |

| DNY1250 | 1250mm | 7-12.5 | 113-188 | 65%-84% | 0.75kw | 0.37kw | 0.37kw | 2600*1800*2270mm |

| DNY1500 | 1500mm | 9.5-15 | 143-240 | 65%-84% | 0.75kw | 0.37kw | 0.37kw | 2600*2050*2270mm |

| DNY1500 | 1500mm | 12-20.5 | 180-308 | 65%-84% | 0.75kw | 0.55kw | 0.55kw | 3190*2300*2510mm |

| DNY1750 | 1750mm | 15-24.5 | 225-368 | 65%-84% | 1.1kw | 0.55kw | 0.55kw | 3190*2300*2510mm |

| DNY2000 | 2000mm | 18-30 | 270-450 | 65%-84% | 1.5kw | 0.75kw | 0.75kw | 3190*2550*2510mm |

| DNY2500 | 2500mm | 25-35 | 300-550 | 65%-84% | 2.2kw | 1.1kw | 1.1kw | 4300*3300*2850mm |

| DNY3000 | 3000mm | 30-45 | 360-675 | 65%-84% | 3kw | 1.5kw | 1.5kw | 4300*3550*2850mm |

This equipment combines the three functions of regulating tank, drum concentrator and belt filter press, which can not only concentrate the slurry or feed material, but also realize solid-liquid separation, saving floor space .

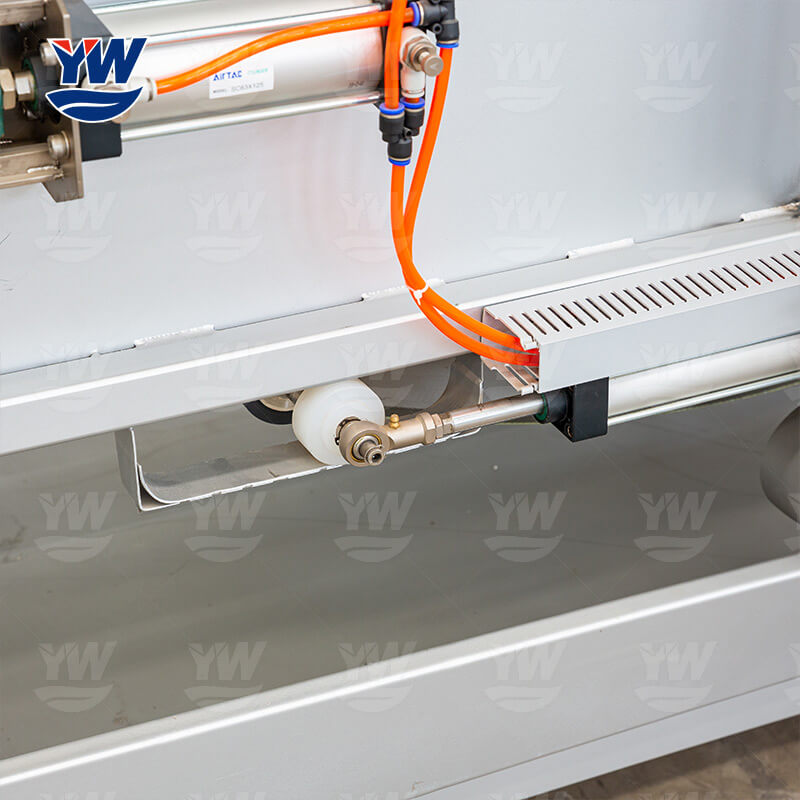

The drum concentrator belt filter press realizes continuous operation to ensure the stable flow of concentrated materials and realize efficient treatment. The equipment is also designed with a self-cleaning system to clean the filter belt and drum while filtering, which not only ensures the working efficiency of the filter belt and drum, but also saves the time for downtime maintenance.

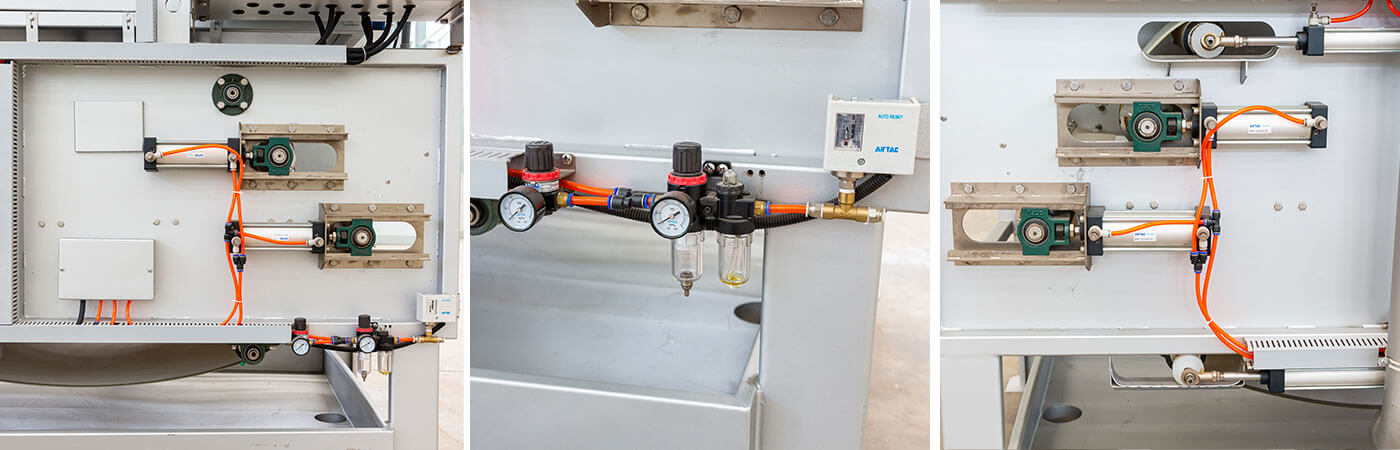

The equipment is equipped with automatic correction, out-of-position monitoring, level monitoring and other automatic systems to ensure smooth operation and consistent performance, these features improve operational efficiency and reduce the need for manual intervention.

The equipment adopts durable structural design and stainless steel 304 material, which can withstand the requirements of the industrial environment, which ensures the reliability and long-term use of the equipment, and reduces the need for maintenance. And the main motor adopts frequency conversion motor to reduce energy consumption and operating costs.

The drum concentrator belt filter press is suitable for a variety of industries and applications where solid-liquid separation and concentration are required. Common applications include sewage treatment, mining, chemical processing and other fields involving slurry or feed materials.