CIP cleaning (Clean-in-Place) is an automated cleaning technology widely used in the food, beverage, pharmaceutical, chemical and other industries. It is used to clean and disinfect production equipment (such as pipes, tanks, reactors, etc.) efficiently and in a standardized manner without disassembling the equipment.

Features of CIP Cleaning

- No need to disassemble the equipment: Cleaning is completed directly at the equipment operating position, reducing downtime and manual operation.

- Automated control: Control cleaning parameters (such as temperature, flow rate, time, cleaning agent concentration) through preset programs to ensure cleaning consistency.

- High efficiency and energy saving: Optimize the use of water, cleaning agents and energy to reduce costs and environmental impact.

- Hygiene and safety: Thoroughly remove residues, microorganisms and contaminants in accordance with industry hygiene standards (such as HACCP, GMP).

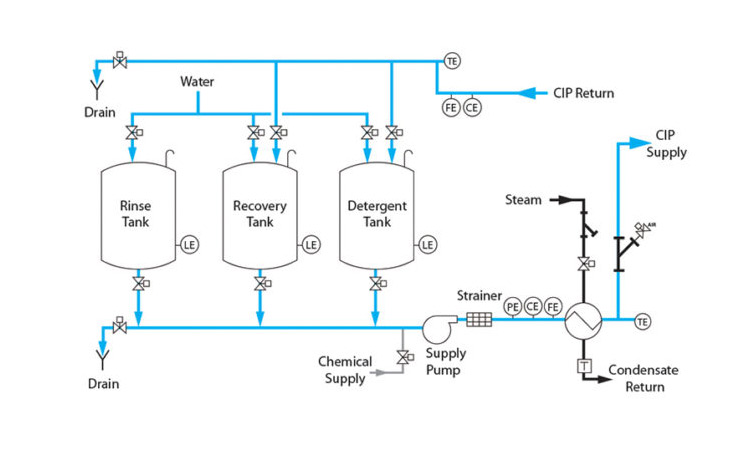

Main Components of CIP System

- Cleaning fluid storage tank: stores cleaning media such as water, acid, alkali, disinfectant, etc.

- Circulation pump: provides flow pressure for cleaning fluid.

- Spraying device: ensures that the cleaning fluid covers the inner surface of the equipment (such as rotating nozzle, fixed spray ball).

- Heating system: controls the temperature of the cleaning fluid (usually high temperature cleaning effect is better).

- Pipes and valves: connect equipment and guide the flow of cleaning fluid.

- Control system: PLC or touch screen controls the cleaning program.

Application Areas of CIP Cleaning

- Food industry: dairy products, beer, juice, sauce production lines.

- Pharmaceutical industry: fermentation tanks, liquid preparation systems, filling equipment.

- Beverage industry: carbonated beverages, bottled water production equipment.

- Chemical industry: reactors, storage tanks, pipeline systems.

Advantages of CIP System

- Reduce the risk of cross contamination: Standardized processes reduce human operating errors.

- Extend equipment life: Regular cleaning prevents corrosion and scaling.

- Compliance: Meet regulatory requirements such as FDA and EU GMP.

- Traceability: Automatically record cleaning data (time, temperature, concentration, etc.).

CIP cleaning is one of the core technologies of modern industrial production. Through automated and standardized processes, it significantly improves equipment cleanliness and production efficiency, while reducing labor costs and resource waste. Its design needs to be combined with specific industry standards and process requirements to ensure safety and economy.