With the increasing demands for production efficiency and product quality in the pharmaceutical industry, Yuwei’s depth filter press, as an efficient and reliable filtration device, is gradually becoming the preferred choice for pharmaceutical companies.

Closed Filtration System: Enhancing Safety and Efficiency in Pharmaceutical Production

This filter press was originally designed for the filtration of plasma. After a long period of development, it can now be widely used for the filtration of food, medicine, and beverages.

- Preventing Contamination: The closed design ensures that the filtration process is conducted in a sterile environment, avoiding contamination from external microorganisms and particles, especially suitable for pharmaceutical production with high cleanliness requirements.

- Improving Efficiency: The closed system reduces material loss during filtration, increases filtration efficiency, and lowers production costs.

High-Efficiency Filtration: Meeting the High Standards of the Pharmaceutical Industry

The pharmaceutical industry has extremely strict requirements for filtration equipment, particularly regarding filtration precision and efficiency. Yuwei’s depth filter press achieves a filtration precision of 0.8 µm, effectively removing tiny particles, bacteria, and other impurities from pharmaceutical liquids, ensuring high purity and quality of the products.

Intelligence and Automation: Enhancing Precision in Production Control

With the advancement of Industry 4.0, intelligence and automation have become important trends in pharmaceutical equipment development. Yuwei’s depth filter press is equipped with a PLC system, enabling fully automated operation and real-time monitoring.

- Smart Sensors: Monitor key parameters such as pressure, flow rate, and temperature during filtration in real-time, automatically adjusting filtration conditions to ensure stable filtration results.

- Automated Operation: Through PLC and IoT technology, the filter press can operate unattended, reducing manual intervention and the risk of operational errors.

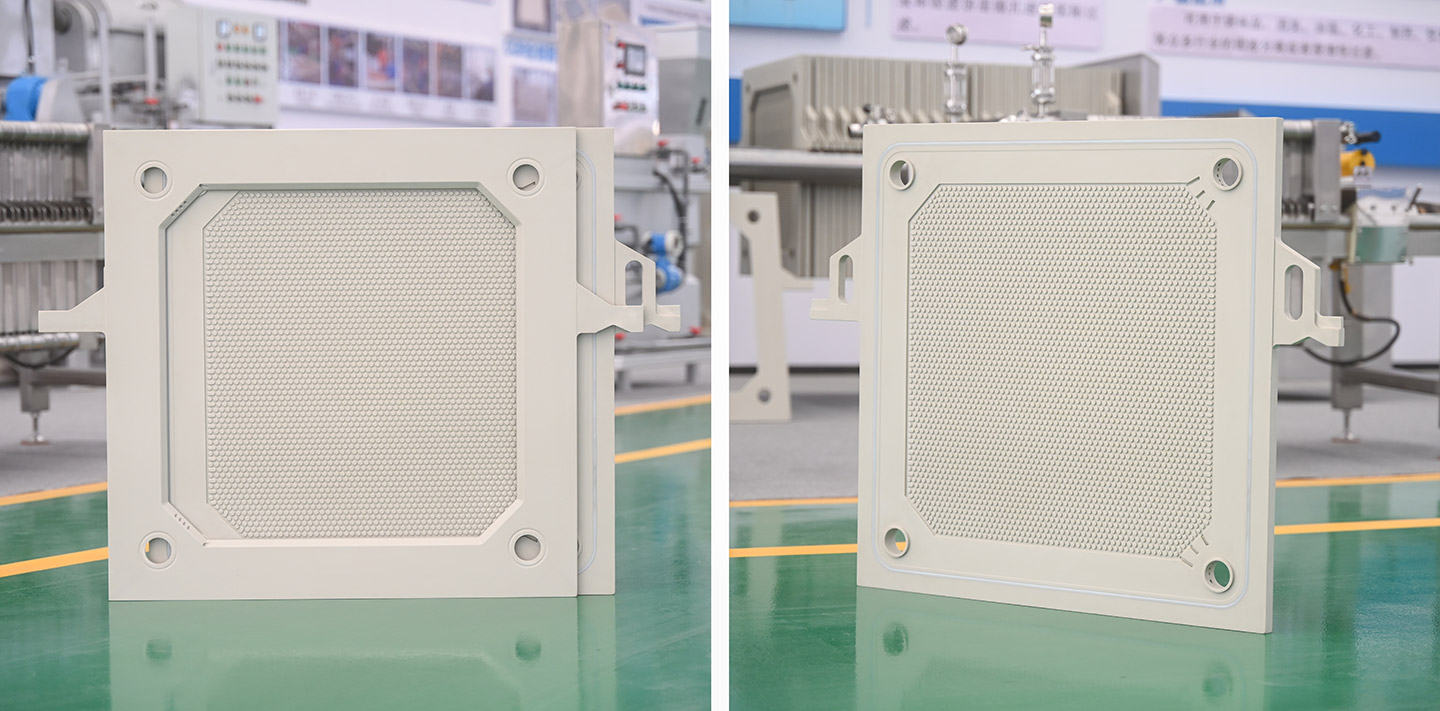

High-Quality Filter Plates: Meeting the Stringent Requirements of the Pharmaceutical, Food, and Beverage Industries

The filter plates are specially designed for the food and pharmaceutical industries, manufactured using German standards, meeting the high hygiene requirements of these industries. The filter plates are designed with hygiene in mind, featuring a dead-space-free design and easy-to-clean structure, ensuring cleanliness and safety during filtration.

- Dead-Space-Free Design: The structure of the filter plates avoids material residue, reducing the risk of bacterial growth, especially suitable for the pharmaceutical and food industries with high hygiene requirements.

- High-Precision Processing: The smooth and flat surface of the filter plates ensures sealing and filtration efficiency, preventing leaks and material loss.

- Corrosion-Resistant Materials: Made from high-quality polypropylene, the filter plates have excellent corrosion resistance and high-temperature performance, suitable for various acidic, alkaline, and high-temperature environments.

Multi-Functional Applications: Suitable for the Pharmaceutical, Food, and Beverage Industries

Yuwei’s German-standard filter plates have a wide range of applications, meeting the diverse needs of the pharmaceutical, food, and beverage industries.

- Pharmaceutical Industry: The filter plates can effectively remove tiny particles and bacteria from pharmaceutical liquids, ensuring high purity and safety of the products.

- Food Industry: Suitable for filtering juices, beer, dairy products, and other foods, ensuring product taste and quality.

- Beverage Industry: The filter plates can efficiently remove impurities from beverages, improving product transparency and stability.

Yuwei’s depth filter press, with its closed filtration system, high-efficiency filtration capabilities, intelligent control, and eco-friendly design, is bringing revolutionary changes to the pharmaceutical industry. As the industry continues to demand higher product quality and production efficiency, the depth filter press will become the preferred equipment for more companies. In the future, Yuwei will continue to focus on technological innovation, driving filtration equipment towards higher efficiency, intelligence, and environmental sustainability, providing higher-quality filtration solutions for the global pharmaceutical industry.