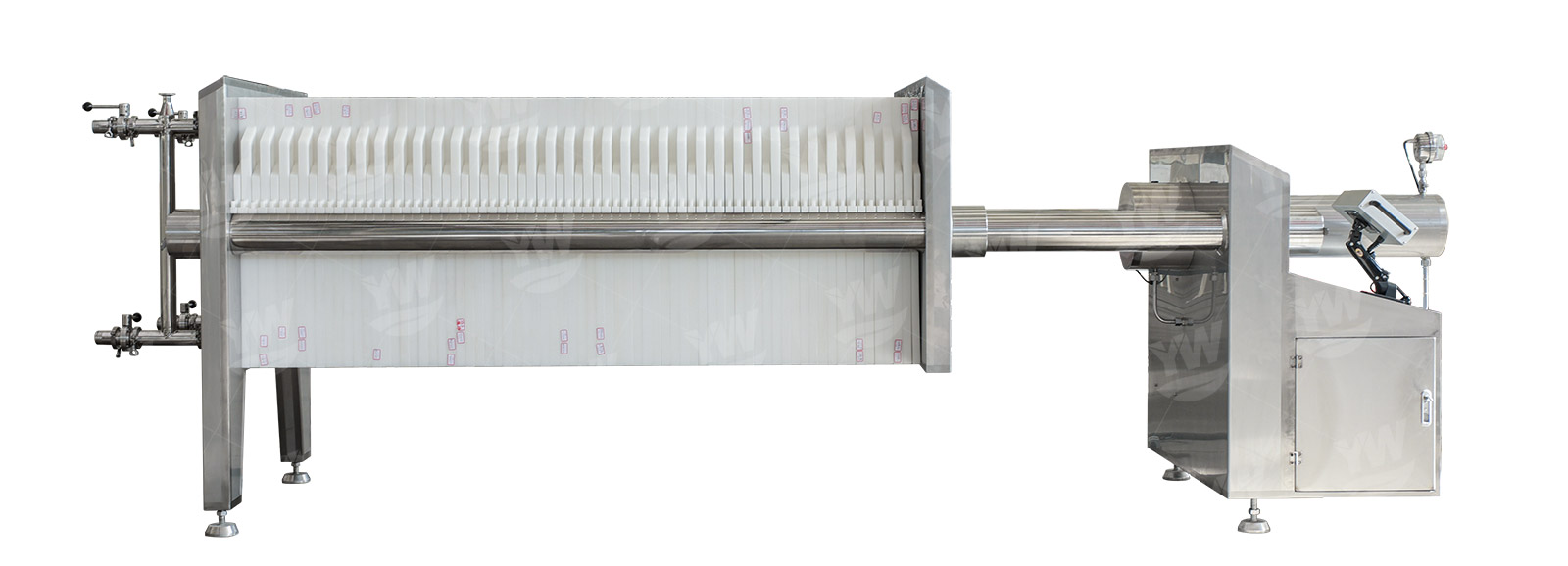

Models : Depth filter press

Filter Plate Size : 885mm

Filter area : 30m²

Plate Shiting : Automatic hydraulic

Operation pressure max : 6 bar

Control : PLC

Temperature : –10°C – +65°C

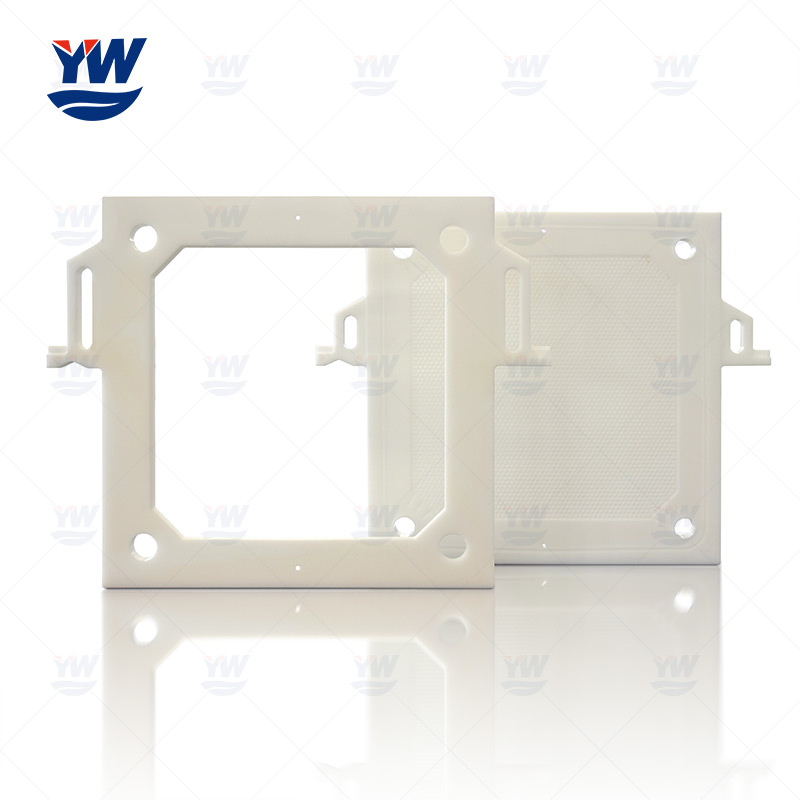

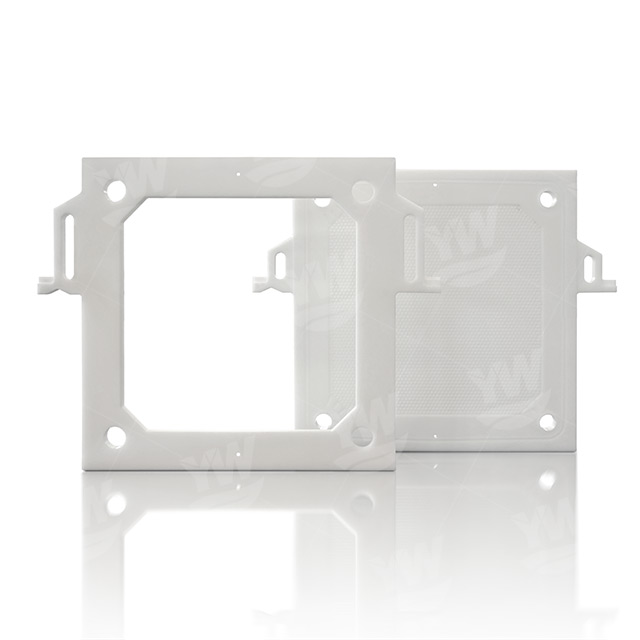

Depth filter press is an enclosed filtration system designed for the special demands of the pharmaceutical industry. The design, material selection, and surface finish all meet the highest hygiene level requirements of the pharmaceutical industry. The sealing of the plate frame component is composed of an annular sealing ring on the filter plate and an inner filter layer, which can ensure 100% sealing without leakage. This is used for the fractionation of blood plasma, cell harvesting of proteins and the clarification filtration of vaccines and antibiotics.

Firstly, the liquid enters the filter press through the inlet, and the unfiltered liquid enters and completely fills the filter frame. Then, the filtered material liquid accumulates at the filtering layer, which occurs on the drainage profile of the filter plate to ensure uniform distribution of the filtered liquid, known as the formation of a filter cake precipitation layer.

A higher recovery rate is ensured by pressing the filter cake dry or cleaning it to the maximum extent possible. After filtration, the filter cake can be collected by opening the filter press.

For CIP cleaning, the entire filter press is sealed and all areas in contact with the material can be rinsed with the cleaning solution. In addition to the filter pad, other filter aids (such as diatomaceous earth) can be added or mixed into the product.

We can provide proof documents of the plate and frame material, such as PP USP classVI certificate