Models : D.E Filters

Max Filter Area : 12m²

Max Work Pressure : 0.55MPa

Control : PLC

Cake Discharging : Automatic

The Horizontal Plate D.E Diatomite Filter Machine adopts Swiss and Italian filtration technology and German manufacturing technology. It has the characteristics of long filtration cycle, high efficiency, stable filtration quality, low filtrate loss, high degree of automation and complete configuration. It is mainly used for clarification and filtration of liquid products in liquor, beer, wine, beverages, sauce and vinegar, as well as medicine and chemical industry.

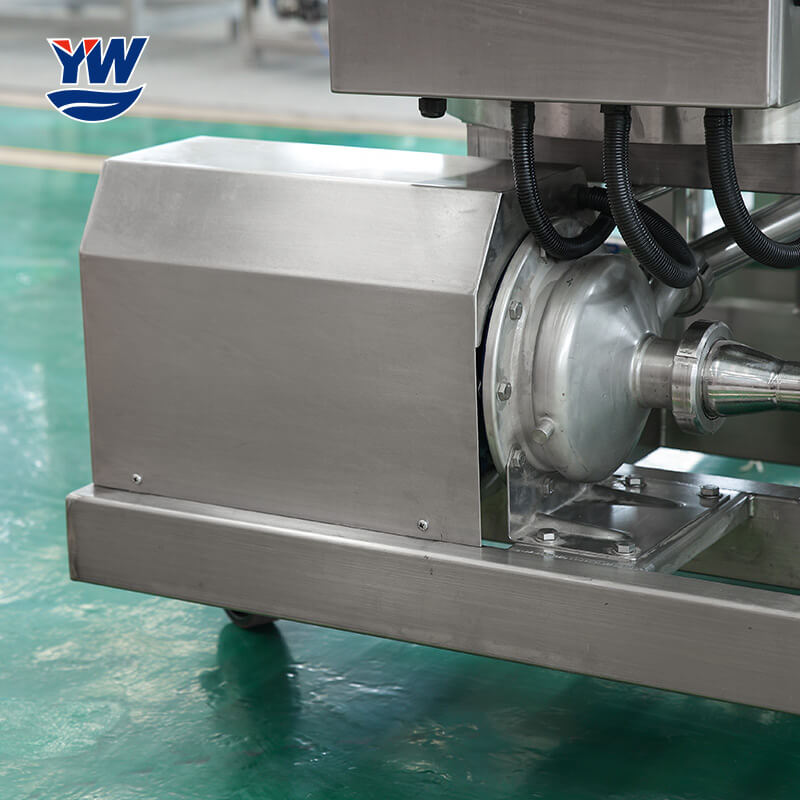

Hydraulic coupling

Sight glass

Cake discharge port

Residual liquid filtration tank

Filter disc

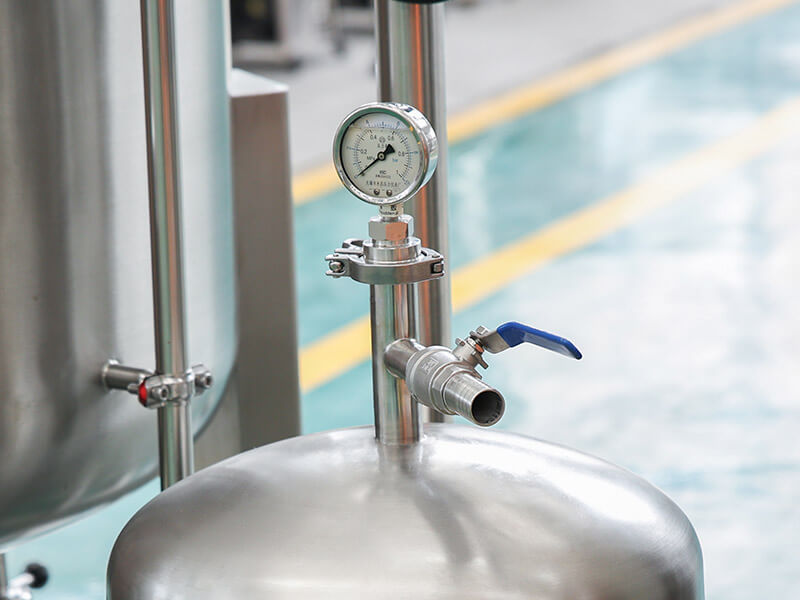

Pressure gauge

Diatomaceous earth mixing tank

Mixing reducer

Pre-coating and addition pipelines

Electric cabinet

Feeding pump

Pressure gauge

The Horizontal Plate D.E Diatomite Filter Machine consists of a filter body, a filter transmission system, a mixing and addition device, a wine pump, a residual liquid filter tank, a pipeline system and an electrical control system. The main body of the filtration includes the filter tank and the spindle of the filter disc; the filtration transmission system consists of a drive motor, a pulley, a hydraulic coupling, a transmission central shaft and an earth discharge device; the mixing and adding device consists of a mixing tank, a stirring motor and a stirring device. Metering pumps, etc.; the pipeline system includes liquid inlet and outlet and circulation pipelines, residual liquid discharge and recovery pipelines, pre-coating and adding pipelines, exhaust and cleaning pipelines, pumps and valves, and pressure gauges.

The cone-shaped filter disc used in this machine is placed horizontally and can support itself. Its high-strength double-sided stainless steel wire filter screen has a flat and smooth surface, is strong and reliable, and has a long life. The supporting cone disc adopts a rib-type structure. It is helpful to achieve the hygienic requirements of stable filtration and cleaning of liquids. In order to achieve safe filtration and hygienic requirements for liquids, liquid filtration is carried out in fully enclosed high-quality stainless steel polished containers and sanitary piping systems; a diverter plate is set at the inlet of the filtrate to make the liquid flowing in a vortex state in the pipeline, through splitting and slowing down, laminar flow is gradually formed to ensure uniform pre-coating of each filter disc and stable filter layer formation.

The metering pump selected for this machine is a diaphragm metering pump. It is produced using Swiss technology. It has a simple structure and accurate metering. It can adjust the amount of diatomaceous earth and other filter aids added at any time according to the turbidity of the filtrate to be filtered.

The filtrate to be filtrate passes through the action of the centrifugal pump and the diatomite mixture quantitatively output by the metering pump, and enters the filter tank through the pipeline, and is filtered by the diatomite or other filter aids on the filter plate, and the yeast and other large particles are removed. Some larger fungi, solid particles and impurities are separated, and the filtered clear liquid is discharged.

| Item | Specification | |||

| Disc Qty (pcs) | 35 | 31 | 25 | |

| Filter Area(m²) | 12 | 10 | 8 | |

| Max Work Pressure (MPa) | 0.55 | |||

| Total Power (KW) | 13.75 | |||

| Sterilization Temperature (°C) | 100 | |||

| Flow Rate (hl/hour) |

Wine | 100—150 | 70—120 | 50 —80 |

| Juice | 80—160 | 60— 120 | 40 —80 | |

| Syrup | 60—120 | 45—90 | 30— 60 | |

| Sauce | 80—150 | 60— 120 | 40— 80 | |

| Vinegar | 100— 180 | 75—140 | 50— 100 | |

| Liquor | 150— 200 | 150— 220 | 100— 150 | |

| Dimension | Height | 2760 | 2550 | 2350 |

| Length × Width | 2300×1250 | |||

| Weight(kg) | 1680 | 1600 | 1520 | |