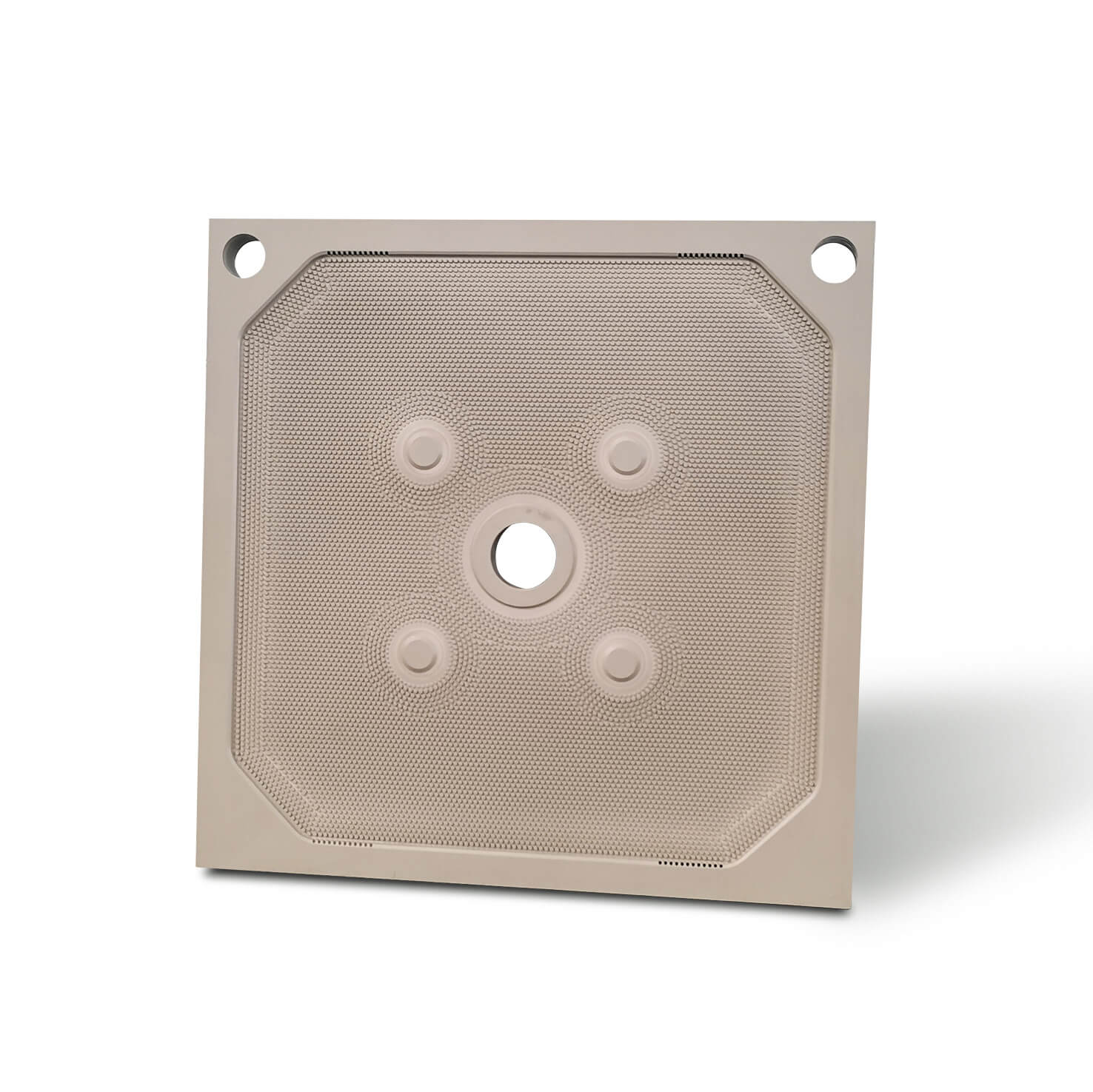

Material : PP /modified PP.

Operating temperature : -10~105 °C(14~221°F)

Pressure Rated : max. 30bar.

Dimension : 250x250mm to 2500x2500mm.

Typical application : Plasma filtration.

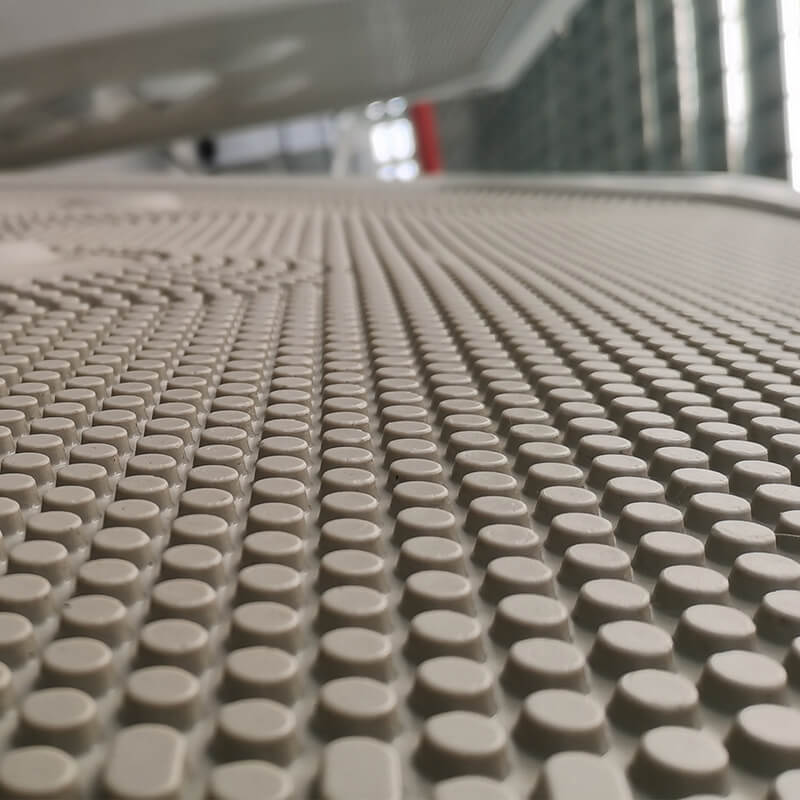

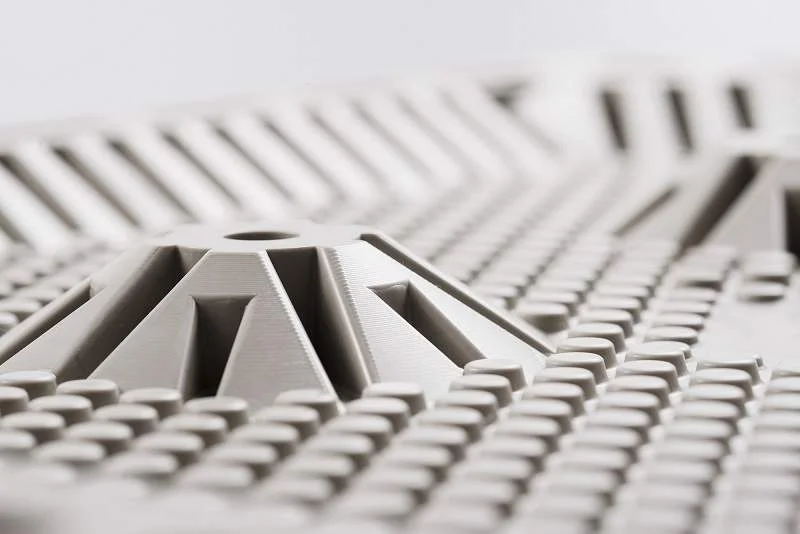

Filter plates are made from high molecular polypropylene (PP) by compression moulding or injection moulding process. For different applications, we can modify base material by adding different additives or modifiers, to improve filter plate’s chemical resistance and mechanical strength under the condition of high corrosive, high temperature or high pressure.

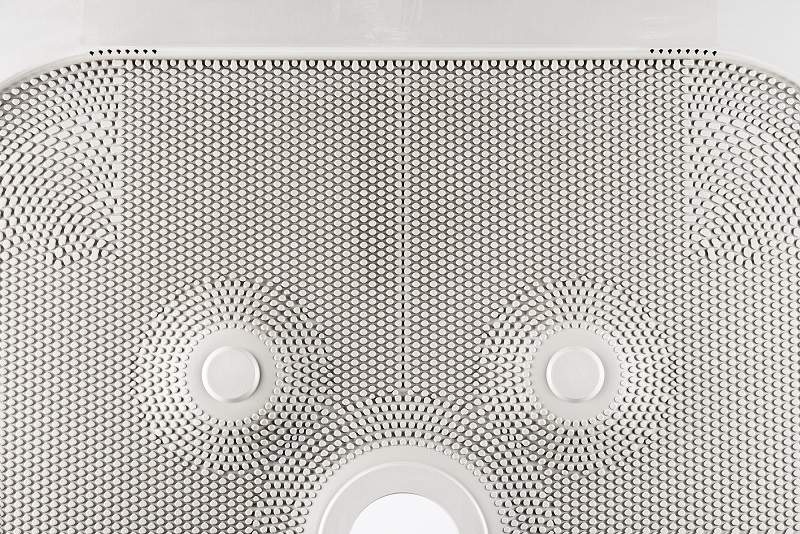

Our membrane filter plate has flexible membrane leaves(diaphragms) which can be applied max. 30 bar squeeze pressure to achieve a even drier cake. In addition, membrane plate has a better wash configuration to improve cake wash efficiency.

We can customize compound or filter plate depending on customer’s requirement. High molecular PP(MFR 0.2~0.5 ) is recommended to ensure a high tensile strength.

If necessary, plate surface or filtrate discharge channels can be polished to Ra 0.8.

Chamber filter plates can be solely used as “chamber filter plate pack”, or be mixed with membrane filter plates to form a mixed “membrane filter plate pack”.

German standard chamber filter plates are moulded with pressing forces up to 4000 tons and 160°C mold temperature, which is unique for this kind of moulding technique. These processing conditions maintain the high physical property profile of our materials of construction.

We can provide welded and detachable (replaceable) membrane filter plates. Body plate and membrane leaf are compression molded up to 60 bar pressure to keep its high strength and offers a high elasticity. The modified polyolefin (majority PP) membrane material, has outstanding temperature resistance, mechanical stress resistance and chemical resistance.

German standard membrane filter plate is suitable for cake washing or purification by means of core washing and corner washing. This can substantially reduce washing time and washing water consumption.

Every side of CGR filter plate has a cloth groove to caulk and fix filter cloth, and one rubber gasket embedded between the sealing surfaces of two plates. The filtrate or washing water is hermetically sealed and can not leak from plate’s sealing edge due to filter cloth’s capillary effect, reducing the pollution by volatile, flammable and explosive substances or products which harm the environment. The sealing edges of filter plate are easy to clean to prevent cake sticking.

CGR plates are suitable for applications which slurries contain volatile substances or toxic and harmful substances.

We can process different compounds of polyolefin materials, such as PP, TPE, POE, PE, with various stabilizers and additives or inorganic fillers in line applications requirements.

For different industrial applications, feeding port position, filtrate discharge and cake washing configuration, air blowing and other flow channel designs, can be recommended and optimized.

Individual raw material compounds have their specific ways to be converted: we can select injection molding and extrusion molding or compression molding or other conversion methods. In our workshop we manage to minimize manual operation mistakes by using a high degree of automation with PLC control in all steps of production, to ensure the stability of product quality.

We can provide sizing of filter presses, pump, pipe valve layout, filtration and cake washing process design.

The plate and frame process features homogeneous filter cake production and excellent washing results. As well as filter cloths, other filter media can be used such as paper or layered disposable filters.