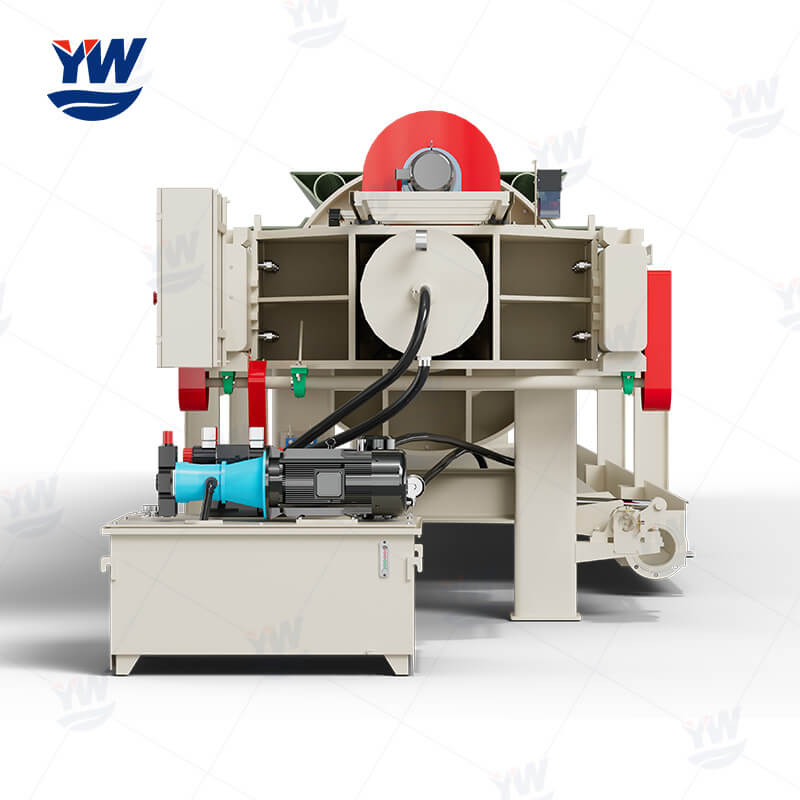

Models : Chamber Filter Press

Material : Carbon Steel

Closing Method : Hydralic

Plate Shiting : Automatic

Filtration pressure : 0.6-2.0MPa

Filtration Area : 20-140m²

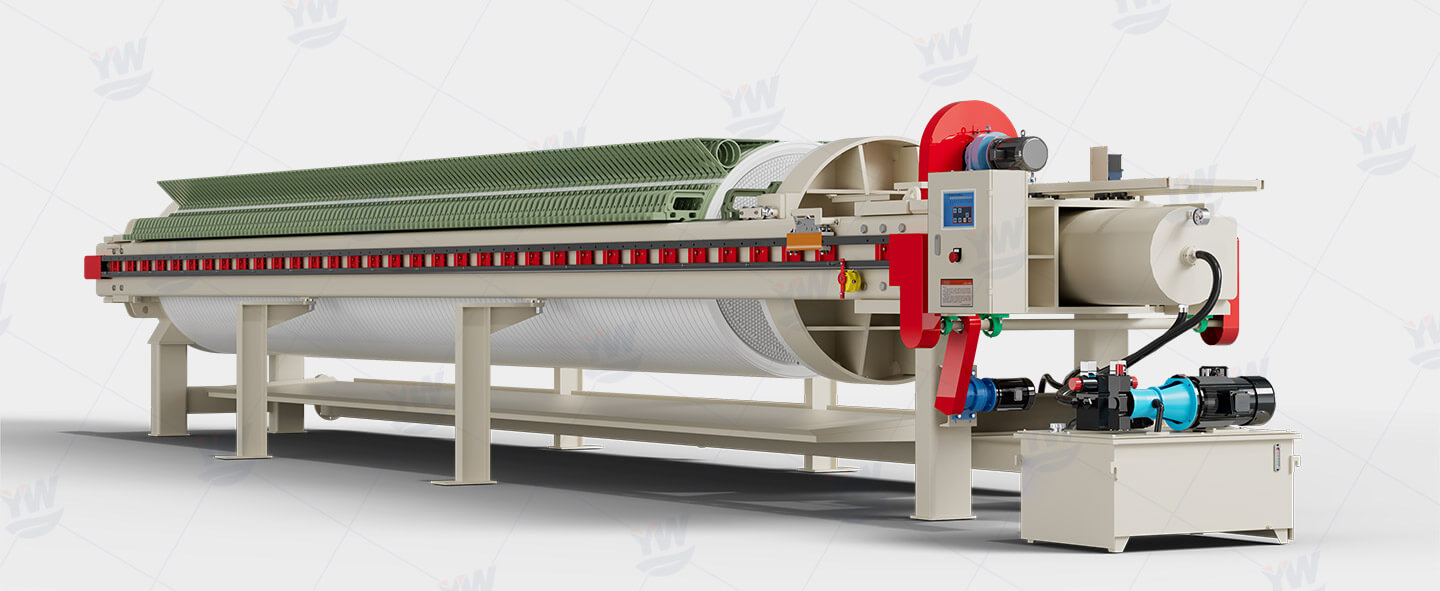

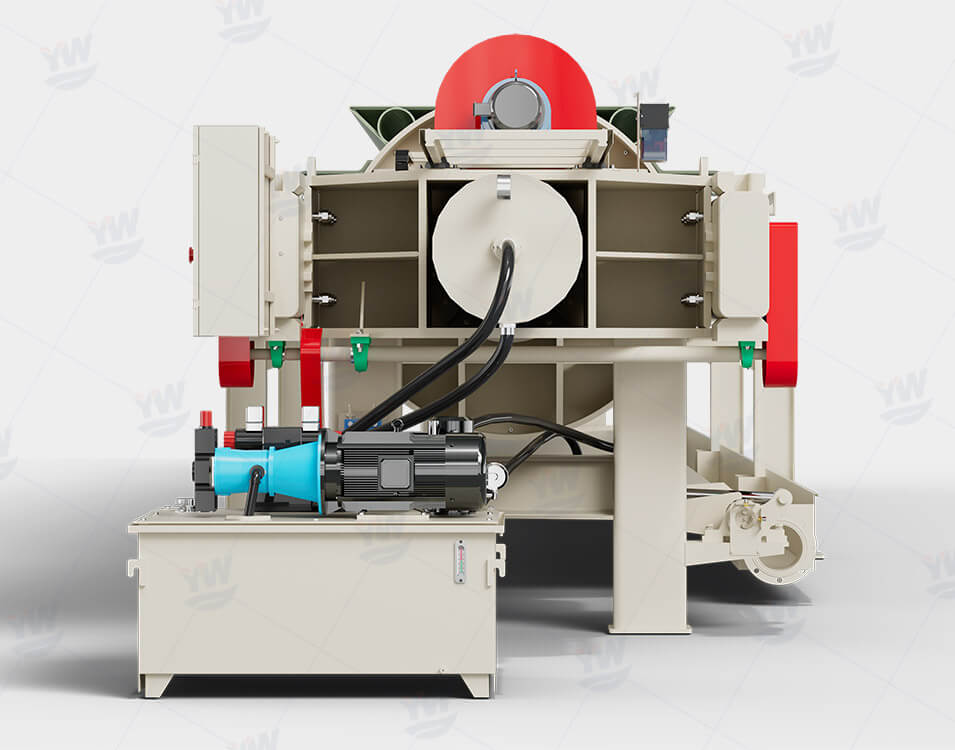

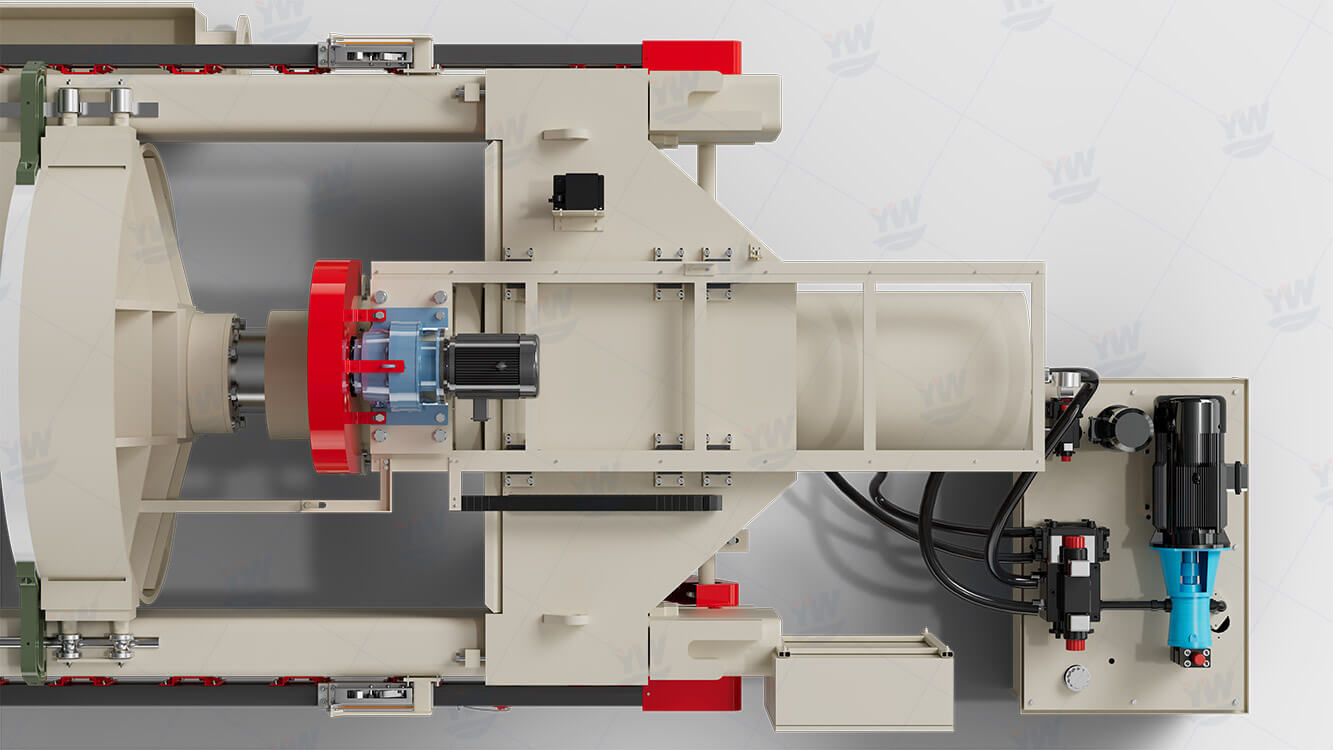

The high-pressure round plate filter press is a kind of equipment improved on the basis of the square filter plate and combined with the needs of the industry. Although there are obvious differences in appearance, the working principle is the same as that of the ordinary chamber filter press. The biggest advantage of the high-pressure round plate filter press is that the round plate filter press has the advantages of stable operation, high feed pressure, and low moisture content of the filter cake. Compared with the ordinary plate and frame filter press, the feeding pressure of the high-pressure round plate filter press can reach 4.0MPa.

| Model | Filter Area (m²) |

Plate size (mm) |

Cake thickness (mm) |

Filter chamber volume (L) |

Plate QTY (pcs) |

Filtration pressure (MPa) |

Weight (Kg) |

Dimensions L×W×H(mm) |

| XA40/Φ800-25 | 40 | Φ800 | 25 | 499 | 40 | 1.0-1.6 | 4554 | 4300×1100x1060 |

| XA50/Φ800-25 | 50 | 621 | 50 | 5150 | 4820×1100×1060 | |||

| XA60/Φ800-25 | 60 | 753 | 60 | 9710 | 5340×1100×1060 | |||

| XA70/Φ800-25 | 70 | 875 | 70 | 5760 | 5860×1100×1060 | |||

| XA80/Φ800-25 | 30 | 1000 | 30 | 6860 | 6200×1100×1060 | |||

| XA80/Φ800-30 | 30 | Φ1000 | 30 | 1210 | 59 | 1.0-1.6 | 6652 | 7254×1311×1399 |

| XA90/Φ1000-30 | 90 | 1350 | 66 | 6848 | 7709×1311×1399 | |||

| XA100/Φ1000-30 | 100 | 1500 | 74 | 7072 | 8229×1311×1399 | |||

| XA110/Φ1000-30 | 10 | 1650 | 31 | 7268 | 8684×1311×1399 | |||

| XA120/Φ1000-30 | 120 | 1800 | 88 | 7464 | 9591×1311×1399 | |||

| XA130/Φ1000-30 | 130 | 1950 | 96 | 7688 | 10111×1311×1399 | |||

| XA140/Φ1000-30 | 40 | 2100 | 103 | 7884 | 10566×1311×1399 |

The filtration pressure of a general plate and frame filter press is generally around 0.6Mpa, and the filtration pressure of a high-pressure circular filter press can reach 1Mpa-2.5Mpa; Due to the low filtration pressure of the filter press, it is necessary to add flocculant or flocculant to condition the filter material before filtration, improve the filtration performance of the material, and enhance the filterability of the material before achieving a satisfactory filtration effect. The high-pressure filtration technology adopted by Yuwei high-pressure circular filter press has a good filtration effect, which can make the material dehydrate more thoroughly, thereby increasing the solid content of the mud cake, and the volume of the mud cake filtered by the general filter press will be much larger. Shrinkage effectively saves the transportation cost of mud cake, and the filtration speed is fast, which can effectively shorten the filtration time.

Due to its high pressure and good sealing properties, it is widely used in stone industry, ceramic industry, kaolin, bentonite, activated soil, building materials, sand washing, mining, paper mills, breeding plants and other industries.