Material: Stainless Steel,Carbon Steel

Filter precision : 10-200(μm)

Filter Area : 2-200(m2)

Max Flow : 1-800(t/h)

Working Pressure : 0.1-0.4(Mpa)

Horizontal pressure leaf filter is an enclosed filtration system and can be fully automated. Horizontal pressure leaf filter for high flow fluid with low solid content, it takes a larger filter area than vertical pressure leaf filter. It is widely used in chemical, pharmaceutical oil and food industries for the filtration of liquids.

Horizontal pressure leaf filters are an effective and reliable method for the filtration of liquids in industrial settings. However, they may be less suitable for smaller scale operations due to their relatively large size and high cost compared to other filtration methods.

| Model | Filter cake volume | Processing power | Workpressure | Filtering cylinder volume | I/O Connection | Discharging outlet | Filter spacing | Weight | ||

| Grease | Resin | Drinks | ||||||||

| YWBL-2 | 30L | 0.4-0.6(t/h) | 1-1.5(t/h) | 1-2(t/h) | 0.1-0.4(Mpa) | 120L | DN25 | DN100 | 50mm | 150Kg |

| YWBL-4 | 60L | 0.8-1.2(t/h) | 2-3(t/h) | 2-4(t/h) | 250L | DN40 | DN125 | 50mm | 180Kg | |

| YWBL-7 | 105L | 1.4-2(t/h) | 3-5(t/h) | 4-8(t/h) | 420L | DN40 | DN150 | 50mm | 326Kg | |

| YWBL-10 | 150L | 2-3(t/h) | 5-8(t/h) | 5-10(t/h) | 890L | DN50 | DN200 | 70mm | 474Kg | |

| YWBL-12 | 240L | 2.4-3.6(t/h) | 6-9(t/h) | 6-12(t/h) | 1190L | DN50 | DN250 | 70mm | 554Kg | |

| YWBL-15 | 300L | 3-5(t/h) | 7-12(t/h) | 8-16(t/h) | 1580L | DN50 | DN250 | 70mm | 815Kg | |

| YWBL-20 | 400L | 4-6(t/h) | 10-15(t/h) | 10-20(t/h) | 1770L | DN65 | DN250 | 70mm | 910Kg | |

| YWBL-25 | 500L | 5-7(t/h) | 12-18(t/h) | 12-24(t/h) | 2200L | DN65 | DN300 | 70mm | 1024Kg | |

| YWBL-30 | 600L | 6-9(t/h) | 14-22(t/h) | 15-30(t/h) | 2770L | DN65 | DN300 | 70mm | 1165Kg | |

| YWBL-36 | 720L | 7-10(t/h) | 16-24(t/h) | 18-36(t/h) | 2870L | DN80 | DN300 | 70mm | 1202Kg | |

| YWBL-40 | 800L | 8-12(t/h) | 20-30(t/h) | 20-40(t/h) | 3500L | DN80 | DN350 | 70mm | 1342Kg | |

| YWBL-45 | 900L | 9-13(t/h) | 22-32(t/h) | 22-44(t/h) | 3630L | DN100 | DN350 | 70mm | 1422Kg | |

| YWBL-52 | 1040L | 10-15(t/h) | 25-40(t/h) | 26-52(t/h) | 4380L | DN100 | DN350 | 75mm | 1900Kg | |

| YWBL-60 | 1200L | 12-18(t/h) | 38-42(t/h) | 30-60(t/h) | 5100L | DN100 | DN400 | 75mm | 2114Kg | |

| YWBL-70 | 1400L | 14-20(t/h) | 35-50(t/h) | 35-70(t/h) | 6940L | DN125 | DN400 | 80mm | 2662Kg | |

| YWBL-80 | 1600L | 16-24(t/h) | 40-60(t/h) | 40-80(t/h) | 8300L | DN125 | DN400 | 80mm | 3882Kg | |

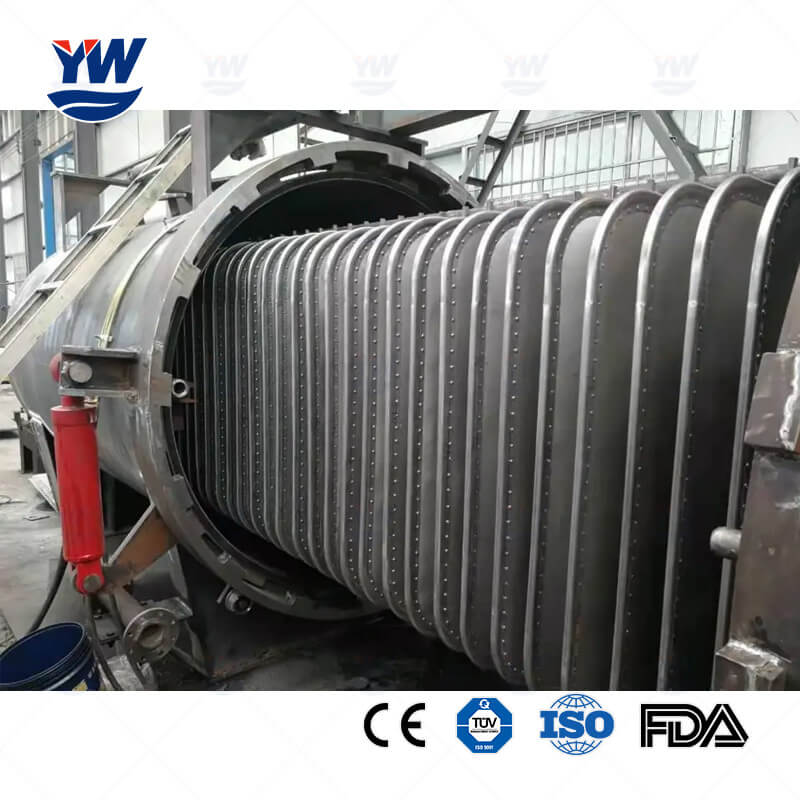

Horizontal pressure leaf filter (shell retraction or bundle retraction) consists of a filter housing, filter leaves, a pneumatic vibrator assembly, a support frame and a hydraulic power back for bonnet ring opening/closing and shell or bundle retraction.

It consists of a horizontal vessel that contains a series of filter plates with vertical filter elements. The liquid to be filtered is pumped into the vessel and flows through the filter elements, which trap any solid particles or debris. The filtered liquid then flows out of the vessel and can be collected for further processing or disposal. Filter leaves are made of 5 layers of stainless-steel (or other metal) wire screen and enjoy a long service life and a low maintenance cost.

When filter cake needs to be recycled or disposed as solids, you may choose dry cake discharge, for example, sugar, cocoa or edible oil filtration, activated carbon removal, molten Sulphur filtration or catalyst recovery. Compressed air, inert gas or steam is commonly used for cake drying before discharging.

If the cake formation is too low for dry discharge, the disposal is cheap (regeneration for wet discharge is shorter) or the cake needs to be transported via a pump, you may choose wet cake discharge, for example, saline water filtration.