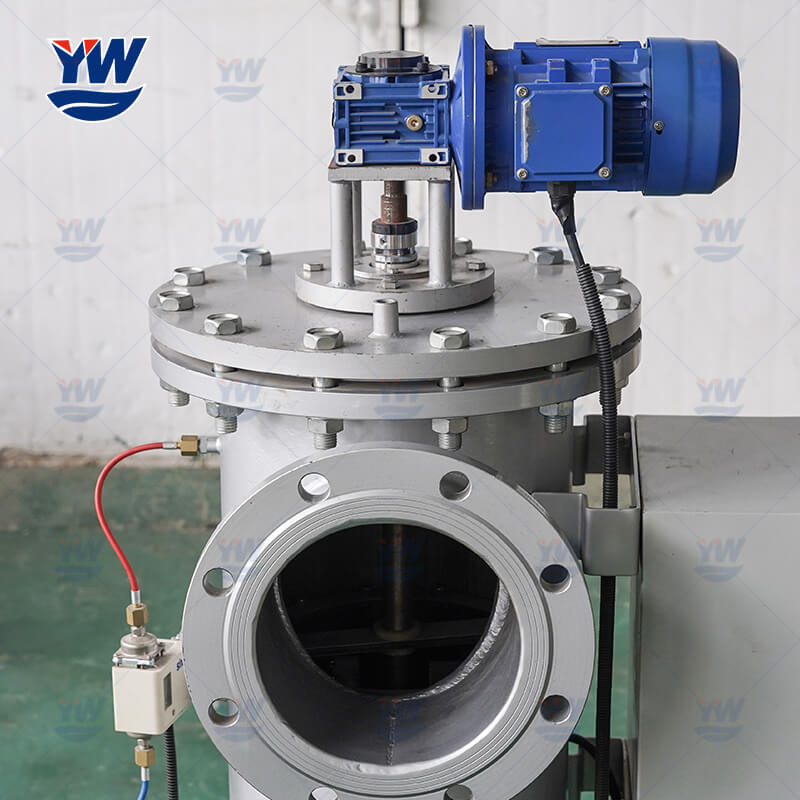

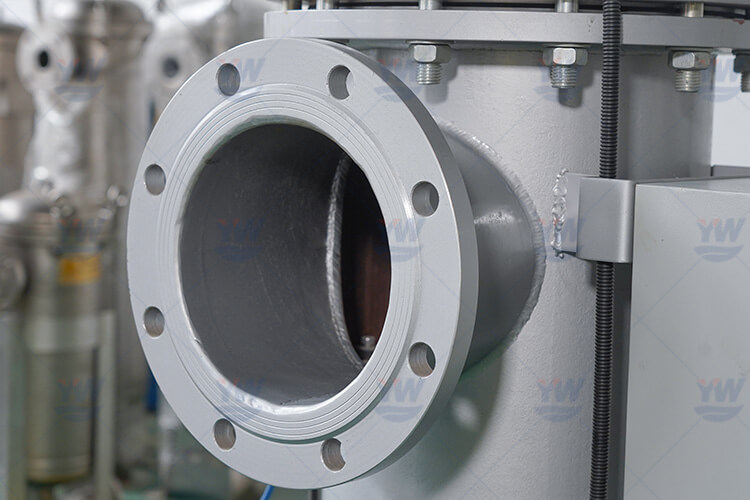

Material: Stainless Steel / Carbon Steel

Capacity: 20-2350m³/h

Max. Pressure: 0.1-1.6MPa

Max. Temperature: 95°C

Filtering Precision: 100-3000μm

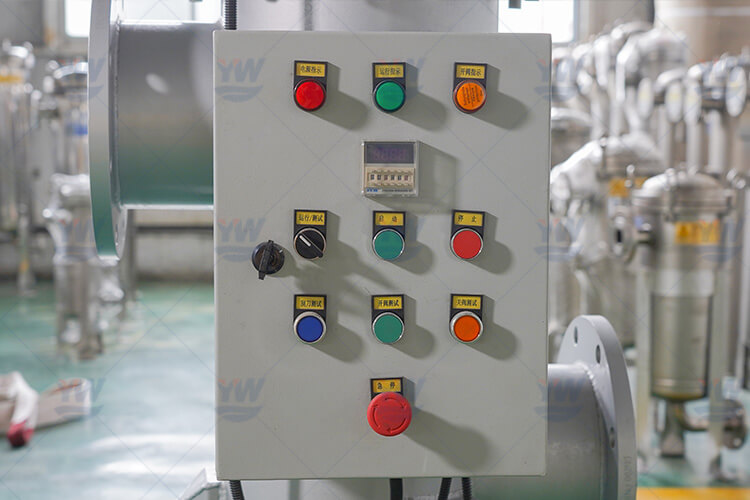

Cleaning Time: 10-60 seconds

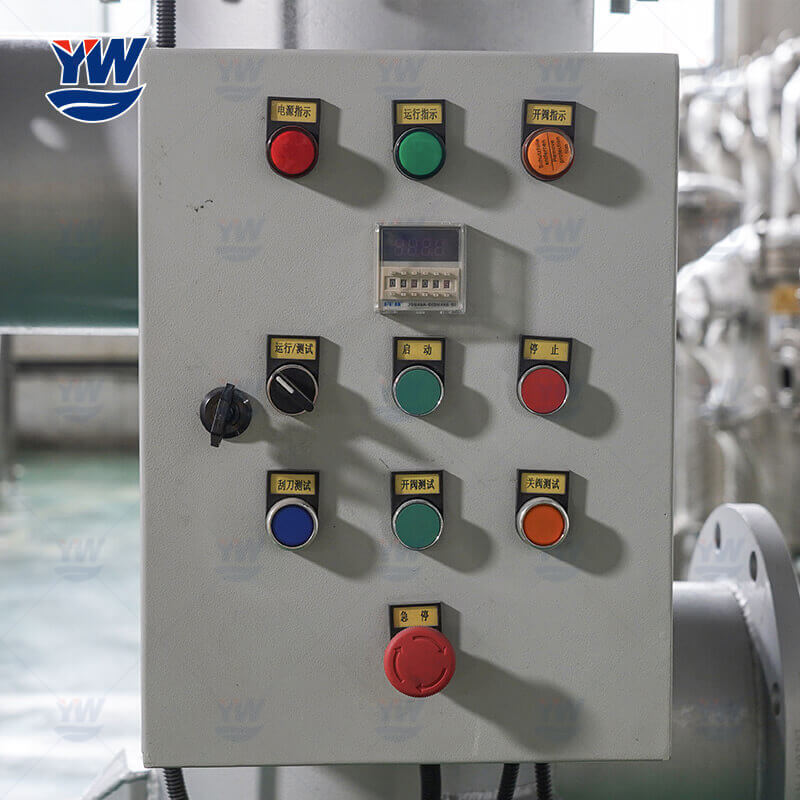

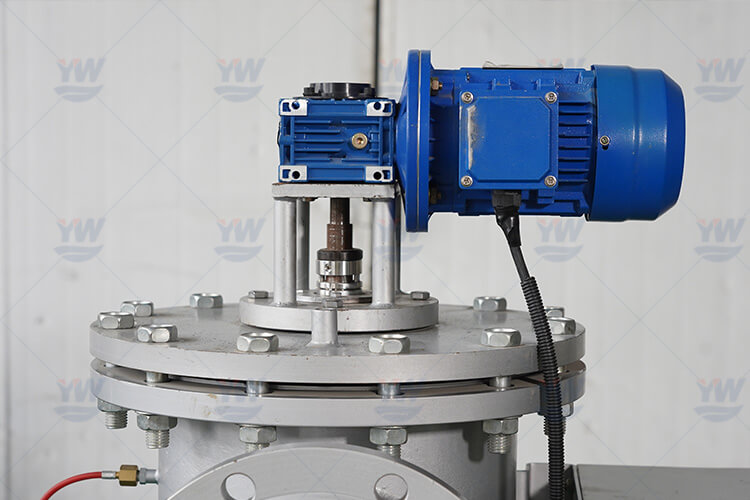

Cleaning Control Type: Pressure Difference / Screw Switch / Button Switch

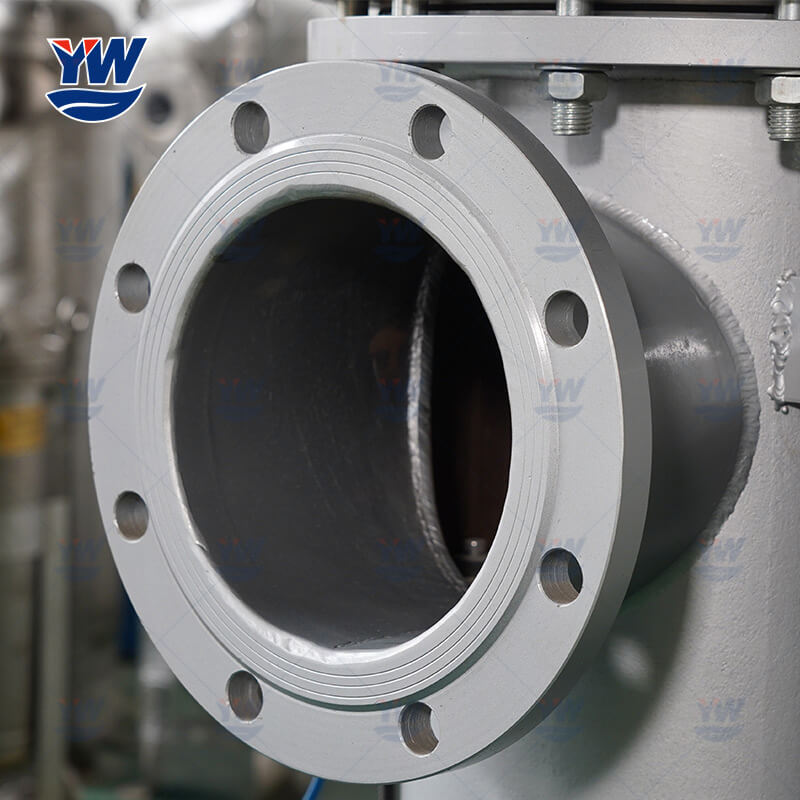

Self cleaning strainer is mainly used in the pretreatment system in raw water treatment, using the filter screen to filter impurities found in water,remove some suspended materials and large particles of impurities such as sediment, rust, red worms, etc., reduce the turbidity of water quality, so as to achieve the effect of pretreatment, extend the service life of other equipment, and ensure the normal operation of the subsequent water treatment system.

Self cleaning strainer adjusts the corresponding filtration accuracy according to the diameter of suspended particles in water. The larger the diameter of suspended particles, the better the interception effect, so the filtration accuracy is different in different water quality. When self-cleaning filtration, it should be checked in advance to confirm the diameter range of suspended particles, so as to customize the filter with corresponding filtration accuracy to ensure the normal operation of the system.

Self cleaning strainer generally does not need to replace the filter element, during the installation process, the technician will set it, sewage through the filter to remove impurities, suspended particles settle and diffuse in the filter screen, and are directly intercepted by the filter screen, thereby reducing turbidity.

During the operation of the self cleaning strainer, the system can automatically identify, when the impurity accumulates to a certain extent, it will automatically send a signal, open the discharge valve, and automatically discharge waste. The whole process is fully automatic, realizing unattended continuous water supply, low maintenance cost, convenient operation and high cost performance.

| Model | Inlet/Outlet | Weight | Filtering Area | Total Height | Capacity |

| YWQX-2 | DN50 | 56Kg | 710cm² | 1400mm | 19t/h |

| YWQX-3 | DN80 | 87Kg | 1165cm² | 1650mm | 45t/h |

| YWQX-4 | DN100 | 106Kg | 1367cm² | 1450mm | 65t/h |

| YWQX-5 | DN125 | 132Kg | 2095cm² | 2100mm | 105t/h |

| YWQX-6 | DN150 | 197Kg | 3014cm² | 2150mm | 150t/h |

| YWQX-8 | DN200 | 248Kg | 5270cm² | 2300mm | 265t/h |

| YWQX-10 | DN250 | 360Kg | 7867cm² | 2450mm | 410t/h |

| YWQX-12 | DN300 | 486Kg | 11414cm² | 2500mm | 590t/h |

| YWQX-14 | DN350 | 653Kg | 15552cm² | 3200mm | 800t/h |

| YWQX-16 | DN400 | 765Kg | 20344cm² | 3300mm | 1050t/h |

| YWQX-18 | DN450 | 814Kg | 25751cm² | 3380mm | 1320t/h |

| YWQX-20 | DN500 | 920Kg | 31786cm² | 3450mm | 1630t/h |

| YWQX-24 | DN600 | 1038Kg | 42295cm² | 3600mm | 2350t/h |

It's widely used for treatment of drinking water, construction circulating water, industrial circulating water, sewage, mining water, and also in various industries: iron, petroleum, electronic, paper making, plastic, automobile etc...