Models : Membrane Filter Press

Filter Plate Size : 1250mm

Control : PLC

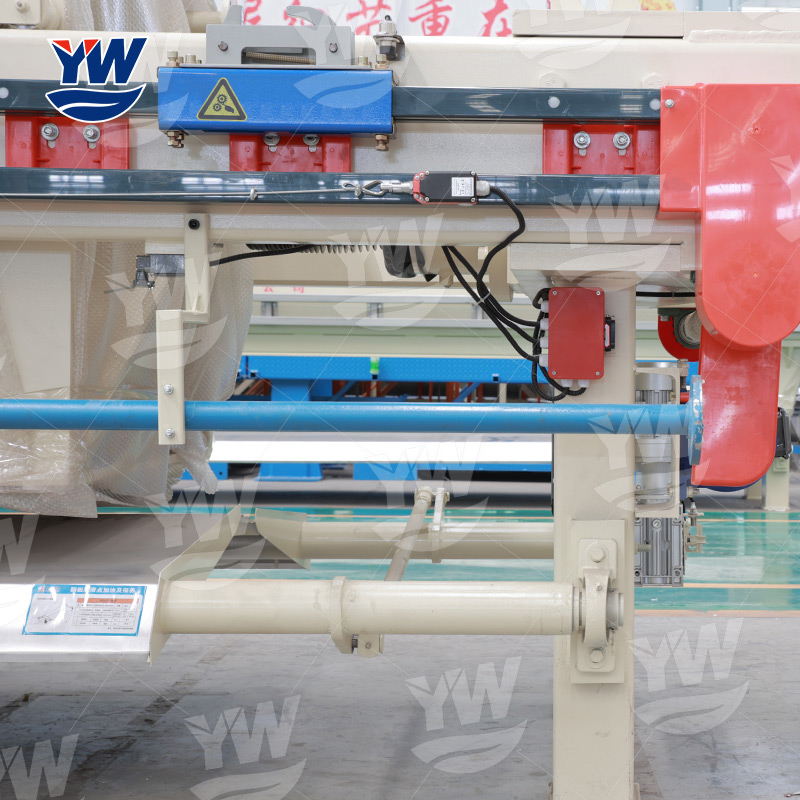

Plate Shifting : Automatic hydraulic

Higher Feeding Pressure : 0.6-1.2MPa

Cake Discharging : Automatic

The fully automatic membrane filter press is the mainstream filtration equipment used in the sugar industry. The equipment adopts advanced German process polypropylene membrane filter plates, innovatively designs a new multifunctional frame, and is matched with Siemens PLC and touch screen control system, making the product technology and performance significantly higher than most similar equipment. This product is widely applicable to the entire process of sugar production, and has unparalleled advantages in filtering thickened mud, sugar carbonation process ,sugarcane juice filtration, saturated juice and other media compared to other equipment. It is characterized by high efficiency, energy conservation, large production capacity, low sugar content in filter mud, and high solid content. The advantages include short washing time, low water consumption, and low dilution.

Widely used in sugarcane sugar production, beet sugar production, raw sugar processing, glucose production, as well as other solid-liquid separation processes in the food, pharmaceutical, and chemical industries.

German standard membrane filter plate is suitable for cake washing or purification by means of core washing and corner washing. This can substantially reduce washing time and washing water consumption.

We can provide welded and detachable (replaceable) membrane filter plates. Body plate and membrane leaf are compression molded up to 60 bar pressure to keep its high strength and offers a high elasticity. The modified polyolefin (majority PP) membrane material, has outstanding temperature resistance, mechanical stress resistance and chemical resistance.

| Model | Filtration area (m²) |

Plate size (mm) |

Filter chamber volume (L) |

Plate Qty. (pcs.) |

Motor power (Kw) |

Weight (Kg) |

Dimensions L*W*H(mm) |

| G30/870-U | 30 | 870*870 | 498 | 23 | 2.2 | 3046 | 3880*1250*1300 |

| G40/870-U | 40 | 623 | 29 | 3593 | 4270*1250*1300 | ||

| G50/870-U | 50 | 789 | 37 | 4057 | 4790*1250*1300 | ||

| G60/870-U | 60 | 955 | 45 | 4597 | 5310*1250*1300 | ||

| G70/870-U | 70 | 1121 | 53 | 5136 | 5830*1250*1300 | ||

| G80/870-U | 80 | 1287 | 61 | 5636 | 6350*1250*1300 | ||

| G50/1000-U | 50 | 1000*1000 | 776 | 27 | 4 | 4352 | 4270*1500*1400 |

| G60/1000-U | 60 | 943 | 33 | 4480 | 4700*1500*1400 | ||

| G70/1000-U | 70 | 1109 | 39 | 5263 | 5130*1500*1400 | ||

| G80/1000-U | 80 | 1275 | 45 | 5719 | 5560*1500*1400 | ||

| G100/1000-U | 100 | 1608 | 57 | 6555 | 6410*1500*1400 | ||

| G120/1000-U | 120 | 1941 | 69 | 7466 | 7260*1500*1400 | ||

| G80/1250-U | 80 | 1250*1250 | 1560 | 29 | 5.5 | 10900 | 4830*1800*1600 |

| G100/1250-U | 100 | 1975 | 37 | 11750 | 5440*1800*1600 | ||

| G120/1250-U | 120 | 2391 | 45 | 12600 | 6060*1800*1600 | ||

| G150/1250-U | 150 | 2911 | 55 | 13620 | 6820*1800*1600 | ||

| G160/1250-U | 160 | 3119 | 59 | 14470 | 7130*1800*1600 | ||

| G200/1250-U | 200 | 3847 | 73 | 15320 | 8200*1800*1600 | ||

| G240/1250-U | 240 | 4679 | 89 | 16170 | 9420*1800*1600 | ||

| G250/1250-U | 250 | 4783 | 91 | 17020 | 9570*1800*1600 | ||

| G200/1500-U | 200 | 1500*1500 | 3809 | 49 | 11 | 26120 | 7140*2200*1820 |

| G250/1500-U | 250 | 4723 | 61 | 26930 | 7730*2200*1820 | ||

| G300/1500-U | 300 | 5637 | 73 | 28160 | 8720*2200*1820 | ||

| G350/1500-U | 350 | 6551 | 85 | 29600 | 10110*2200*1820 | ||

| G400/1500-U | 400 | 7618 | 99 | 31500 | 11260*2200*1820 | ||

| G450/1500-U | 450 | 8532 | 111 | 33400 | 12250*2200*1820 | ||

| G500/1500-U | 500 | 9446 | 123 | 33380 | 13240*2200*1820 | ||

| G600/2000-U | 600 | 2000*2000 | 11901 | 85 | 15 | 54164 | 13030*3000*2500 |

| G700/2000-U | 700 | 13838 | 99 | 58300 | 14390*3000*2500 | ||

| G800/2000-U | 800 | 14945 | 107 | 62460 | 15770*3000*2500 | ||

| G900/2000-U | 900 | 17713 | 127 | 66620 | 17150*3000*2500 | ||

| G1000/2000-U | 1000 | 19651 | 141 | 70780 | 18530*3000*2500 |