Models : Mobile Vehicle-Mounted Filter Press

Material : Carbon Steel

Beam : Carbon Steel

Voltage : 220-380V

Plate Shiting : Automatic

Filter Plate Size : 1500-2000mm

Control : PLC

The mobile vehicle-mounted portable sludge filter press is a comprehensive sewage treatment equipment that integrates sludge dehydration equipment used for sludge treatment with dosing, stirring, sedimentation, and solid-liquid separation. It realizes the flexible movement of sludge treatment equipment and can be used in different sites. The flow work between them is the preferred equipment for sewage treatment in industries such as piling mud and river dredging.

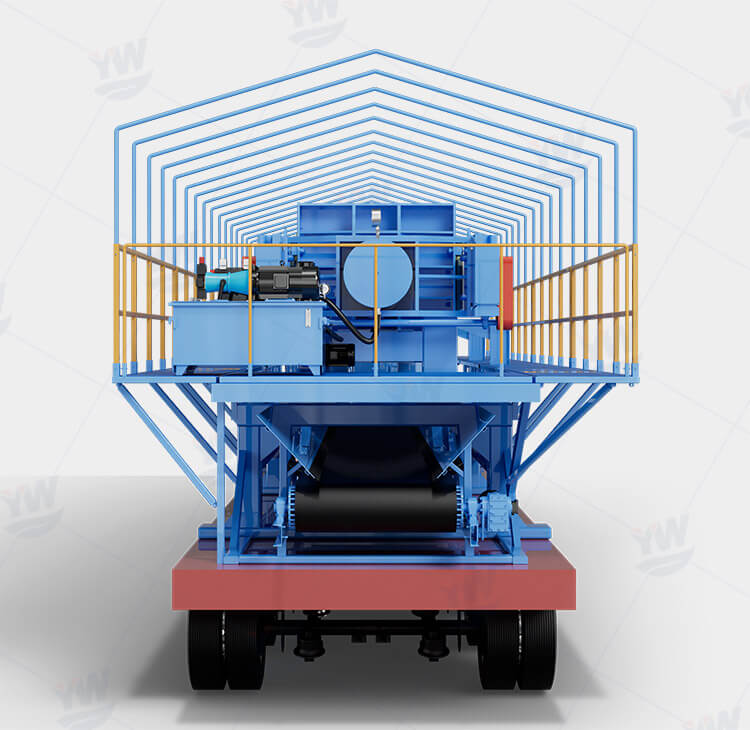

The mobile vehicle-mounted portable sludge filter press is mainly composed of skeleton, filter plates, plate shifting system, drip tray, filter cake conveyor, a hydraulic system and a control system.

The mobile vehicle-mounted portable sludge filter press, through its compact equipment layout and pipeline connection design, can be accommodated in a modified container and moved on the vehicle. The dispersed and unconcentrated sludge sewage can be filtered by the mobile vehicle-mounted filter press. It has high degree of automation, easy operation, reliable performance, fast filtration speed, saves manpower and material resources, improves filtration efficiency, and is safe to use; suitable for field operations and convenient for transportation and transfer.

The mobile vehicle-mounted portable sludge filter press is suitable for on-site dehydration of waste slurry or sewage generated during the construction of environmental pollution sewage emergency treatment and other projects, as well as for some construction sites such as high-pressure jet spray construction or bored piles. The waste mud generated during the construction is dehydrated on-site to form mud cake and clean water, so that the original waste mud transportation discharge is changed to the waste transportation disposal, which reduces the discharge of construction waste mud and the separated clean water can be fully recycled for use the mixing of drilling holes and cement slurry saves water resources and improves the construction environment.