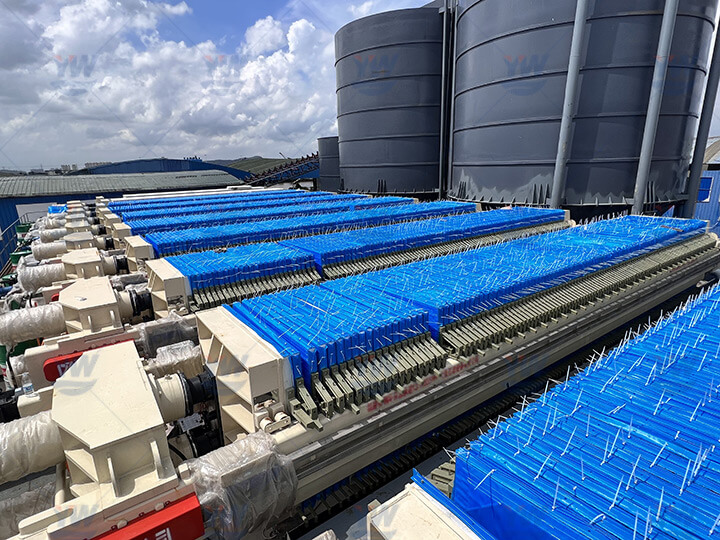

Case information

Sand washing wastewater treatment

10 sets XMZ500-1500 Automatic chamber filter press

- Project: Sand washing wastewater treatment

- Product model: 10 sets XMZ500-1500 Automatic chamber filter press

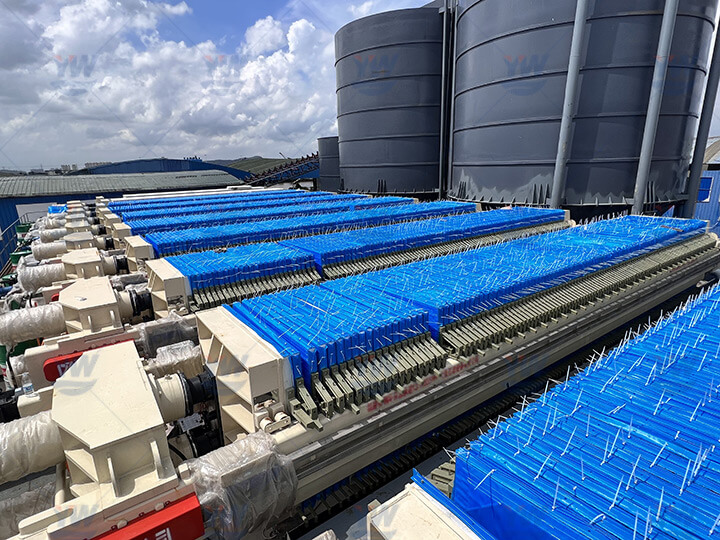

Filter Press become the key part of slurry treatment in Sand washing Plant

With more and more strict quality of sand and stone used in construction and the great rectification in the field of environmental protection, there are more requirements for the equipment related to sand washing plant. It has been proved by practice that filter press is welcomed by more and more sand washing plants. At this paper, we explore the reason why filter press becomes the best choice.

Because of its process requirements, there are large number of water consumption in sand washing plant, resulting in a large number of mud. To save production costs, some plants adopt direct discharging way, which not only pollute the environment, but also cause river blockage. Other plants build a few sedimentation tanks to allow mud to settle naturally, and then dig out the settling sludge. But this way needs high labor cost, large area, high mud moisture content, which is difficult to treat.

This project purchase our company 10 set XMZ500-1500 automatic chamber filter press.

The technological process

- Wastewater and sludge are discharged into a sedimentation tank for sedimentation. At this time, the sludge is affected by gravity and sinks to the bottom of the tank, and is discharged into the mud tank through the sludge lift pump port at the bottom.

- The mud tank is equipped with a mud mixer to treat incoming sludge with varying water content, making the sludge water content uniform and preparing for the next step of pressure filtration.

- The filter piston of the filter press pushes the filter plate tightly, forming a filter chamber when the set pressure is reached. The filter press feed pump draws mud from the bottom of the mud tank and enters the filter through the feed port Chamber, when all filter chambers are filled, pressurized separation is performed to perform solid-liquid separation, and the water content of the separated filter cake is as low as 40%.

- The filter press is located above the mud reservoir, and the separated filter cake directly falls into the mud reservoir for later treatment. The separated purified water flows into the collecting tank and can be put into the sand washing operation again.