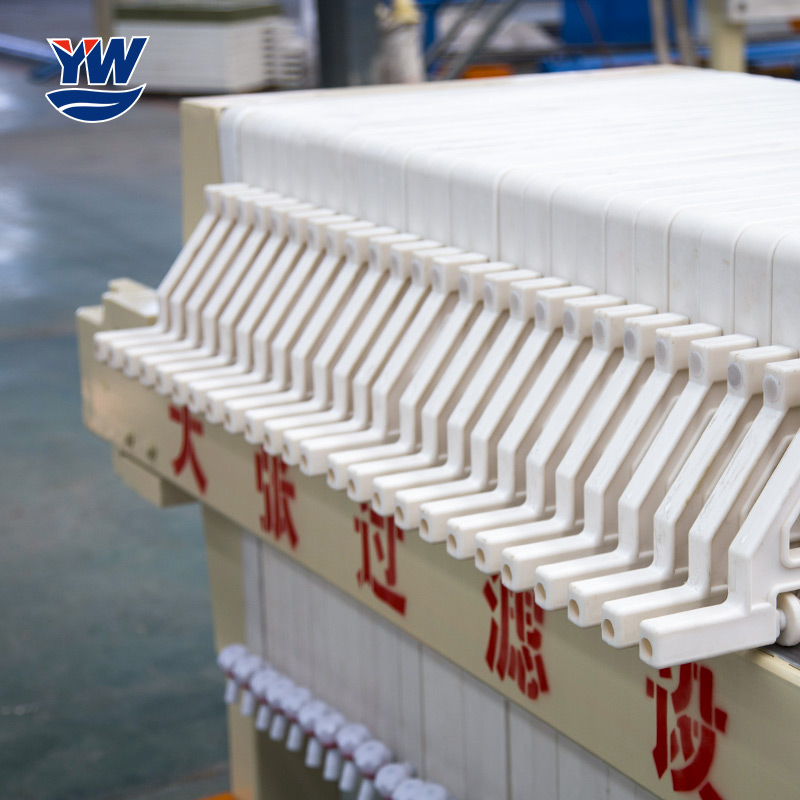

Plate Shifting: Manual Filter Press

Control Method : Control Cabinet

Cake Thickness : 30mm

Filter Area : 4-80m² of Filter Press

Material of Plate : PP Filter Press Plate

Filtration Pressure : ≥0.6Mpa

Motor Power : 2.2KW

The hydraulic chamber filter press uses an electric contact pressure gauge to automatically maintain the pressure value during the working process. During the pressure filtration process, the pressure of the whole equipment is relatively constant, so as to prevent the leakage of slurry and ensure good filtration effect. The whole equipment can be controlled by electric control cabinet through operation, which is easy to operate and stable and reliable. While ensuring work efficiency, it can also save time and manpower. As a kind of intermittent pressure filter equipment, it can be used for solid-liquid separation of various suspensions, such as petroleum, chemical, dye, metallurgy, pharmaceutical, food, papermaking, coal washing, sewage treatment and other fields.

| Model | Plate size | Filter Area | Volume | Plate QTY | Pressure | Power | Weight | Dimensions |

| XM/AY-4/450 | 500mm | 4m² | 60L | 9pcs | ≥0.6MPa | 2.2Kw | 860Kg | 1950*700*900mm |

| XM/AY-6/450 | 6m² | 91L | 14pcs | 910Kg | 2200*700*900mm | |||

| XM/AY-8/450 | 8m² | 121L | 19pcs | 960Kg | 2450*700*900mm | |||

| XM/AY-10/450 | 10m² | 151L | 24pcs | 1010Kg | 2700*700*900mm | |||

| XM/AY-12/450 | 12m² | 182L | 29pcs | 1060Kg | 2950*700*900mm | |||

| XM/AY-15/450 | 15m² | 225L | 36pcs | 1130Kg | 3300*700*900mm | |||

| XM/AY-16/450 | 16m² | 243L | 39pcs | 1160Kg | 3450*700*900mm | |||

| XM/AY-15/630 | 700mm | 15m² | 226L | 18pcs | ≥0.6MPa | 2.2Kw | 1725Kg | 2640*900*1060mm |

| XM/AY-20/630 | 20m² | 297L | 24pcs | 1725Kg | 2940*900*1060mm | |||

| XM/AY-30/630 | 30m² | 452L | 37pcs | 2360Kg | 3590*900*1060mm | |||

| XM/AY-40/630 | 40m² | 595L | 49pcs | 2788Kg | 4300*900*1060mm | |||

| XM/AY-30/800 | 800mm | 30m² | 460L | 28pcs | ≥0.6MPa | 2.2Kw | 2170Kg | 3700*1200*1160mm |

| XM/AY-40/800 | 40m² | 595L | 38pcs | 2450Kg | 4300*1200*1160mm | |||

| XM/AY-50/800 | 50m² | 749L | 47pcs | 2700Kg | 4840*1200*1160mm | |||

| XM/AY-60/800 | 60m² | 902L | 57pcs | 2980Kg | 5440*1200*1160mm | |||

| XM/AY-70/800 | 70m² | 1056L | 67pcs | 3250Kg | 6040*1200*1160mm | |||

| XM/AY-30/870 | 870mm | 30m² | 460L | 23pcs | ≥0.6MPa | 2.2Kw | 2580Kg | 3330*1350*1250mm |

| XM/AY-40/870 | 40m² | 595L | 30pcs | 2925Kg | 3420*1350*1250mm | |||

| XM/AY-50/870 | 50m² | 748L | 38pcs | 3318Kg | 4260*1350*1250mm | |||

| XM/AY-60/870 | 60m² | 902L | 46pcs | 3712Kg | 4700*1350*1250mm | |||

| XM/AY-70/870 | 70m² | 1056L | 54pcs | 4106Kg | 5140*1350*1250mm | |||

| XM/AY-80/870 | 80m² | 1210L | 62pcs | 4561Kg | 5580*1350*1250mm | |||

| XM/AY-50/1000 | 1000mm | 50m² | 736L | 28pcs | ≥0.6MPa | 4Kw | 4072Kg | 4040*1500*1360mm |

| XM/AY-60/1000 | 60m² | 889L | 34pcs | 4468Kg | 4460*1500*1360mm | |||

| XM/AY-70/1000 | 70m² | 1041L | 40pcs | 4863Kg | 4760*1500*1360mm | |||

| XM/AY-80/1000 | 80m² | 1193L | 46pcs | 5259Kg | 5120*1500*1360mm | |||

| XM/AY-100/1000 | 100m² | 1475L | 57pcs | 5985Kg | 5800*1500*1360mm | |||

| XM/AY-120/1000 | 120m² | 1777L | 69pcs | 6776Kg | 6500*1500*1360mm | |||

| XM/AZ-100/1250 | 1250mm | 100m² | 1468L | 36pcs | ≥0.6MPa | 4Kw | 6728Kg | 5020*1500*1360mm |

| XM/AZ-120/1250 | 120m² | 1746L | 43pcs | 7512Kg | 5470*1500*1360mm | |||

| XM/AZ-140/1250 | 140m² | 2063L | 51pcs | 8641Kg | 5990*1500*1360mm | |||

| XM/AZ-160/1250 | 160m² | 2341L | 58pcs | 9540Kg | 6450*1500*1360mm | |||

| XM/AZ-180/1250 | 180m² | 2619L | 65pcs | 10044Kg | 6905*1500*1360mm | |||

| XM/AZ-200/1250 | 200m² | 2896L | 72pcs | 10851Kg | 7360*1500*1360mm | |||

| XM/AZ-220/1250 | 220m² | 3214L | 80pcs | 11765Kg | 7880*1500*1360mm | |||

| XM/AZ-250/1250 | 250m² | 3650L | 91pcs | 12834Kg | 8600*1500*1360mm | |||

| XM/AZ-200/1500 | 1500mm | 200m² | 2998L | 49pcs | ≥0.6MPa | 11Kw | 19530Kg | 6400*2200*1900mm |

| XM/AZ-250/1500 | 250m² | 3594L | 61pcs | 22478Kg | 7225*2200*1900mm | |||

| XM/AZ-300/1500 | 300m² | 4347L | 74pcs | 25526Kg | 8130*2200*1900mm | |||

| XM/AZ-350/1500 | 350m² | 5043L | 86pcs | 28720Kg | 8940*2200*1900mm | |||

| XM/AZ-400/1500 | 400m² | 5796L | 99pcs | 32074Kg | 9880*2200*1900mm | |||

| XM/AZ-450/1500 | 450m² | 6492L | 111pcs | 35086Kg | 10690*2200*1900mm | |||

| XM/AZ-500/1500 | 500m² | 7187L | 123pcs | 38106Kg | 11560*2200*1900mm |

The hydraulic chamber filter press is composed of four parts, frame part, filtering part, hydraulic and electrical control part. The hydraulic pressing part of the filter press is composed of oil cylinder, piston, piston rod, and hydraulic station (motor, oil pump, overflow valve (regulating pressure) reversing valve, pressure gauge, oil circuit, oil tank) connected by the piston rod and the pressing plate. The main advantages of this equipment are less loss when feeding, fast filtering speed, good sealing performance, uniform washing of filter cake, and low water content.

The working principle of the hydraulic chamber filter press is that when the hydraulic pressure is automatic pressure maintaining, the pressure is controlled by the electric contact pressure gauge, and the upper and lower limit pointers of the pressure gauge are set at the value required by the process. When the compression force reaches the upper limit of the pressure gauge, the power supply is cut off and the oil pump stops power supply. The compression force decreases due to the possible internal and external leakage of the oil circuit system. When the pressure reaches the lower limit pointer of the pressure gauge, the power supply will be connected, and the oil pump will start to supply oil. When the pressure reaches the upper limit, the power supply will be cut off, and the oil pump will stop supplying oil, so as to achieve the effect of ensuring the pressure in the process of filtering materials