Material: Stainless Steel / Carbon Steel

Capacity: 20-2350m³/h

Max. Pressure: 0.1-1.6MPa

Max. Temperature: 95°C

Filtering Precision: 100-3000μm

Cleaning Time: 10-60 seconds

Cleaning Control Type: Pressure Difference / Screw Switch / Button Switch

Self cleaning filter is a kind of automatic precision equipment that uses the filter screen to directly intercept the impurities in the water, remove the suspended solids and particulate matter in the water body, and purify the water quality. It can reduce the generation of system fouling, bacteria and algae, and rust, so as to protect the normal operation of other equipment in the system.

Yuwei self cleaning filter overcomes many shortcomings of traditional filtration products, such as small processing capacity, frequent cleaning of filter bags and filter elements, filtration parts need to be disassembled and cleaned, and the filter status cannot be monitored. It can filter raw water and automatically filter the filter. The net is used to clean and discharge the sewage, and the system filters continuously during the cleaning and discharge, which can monitor the working status of the filter, and the degree of automation is high. It covers the needs of various filtration precisions from 50um to 800um.

| Model | Inlet/Outlet | Weight | Filtering Area | Total Height | Capacity |

| YWQX-2 | DN50 | 56Kg | 710cm² | 1400mm | 19t/h |

| YWQX-3 | DN80 | 87Kg | 1165cm² | 1650mm | 45t/h |

| YWQX-4 | DN100 | 106Kg | 1367cm² | 1450mm | 65t/h |

| YWQX-5 | DN125 | 132Kg | 2095cm² | 2100mm | 105t/h |

| YWQX-6 | DN150 | 197Kg | 3014cm² | 2150mm | 150t/h |

| YWQX-8 | DN200 | 248Kg | 5270cm² | 2300mm | 265t/h |

| YWQX-10 | DN250 | 360Kg | 7867cm² | 2450mm | 410t/h |

| YWQX-12 | DN300 | 486Kg | 11414cm² | 2500mm | 590t/h |

| YWQX-14 | DN350 | 653Kg | 15552cm² | 3200mm | 800t/h |

| YWQX-16 | DN400 | 765Kg | 20344cm² | 3300mm | 1050t/h |

| YWQX-18 | DN450 | 814Kg | 25751cm² | 3380mm | 1320t/h |

| YWQX-20 | DN500 | 920Kg | 31786cm² | 3450mm | 1630t/h |

| YWQX-24 | DN600 | 1038Kg | 42295cm² | 3600mm | 2350t/h |

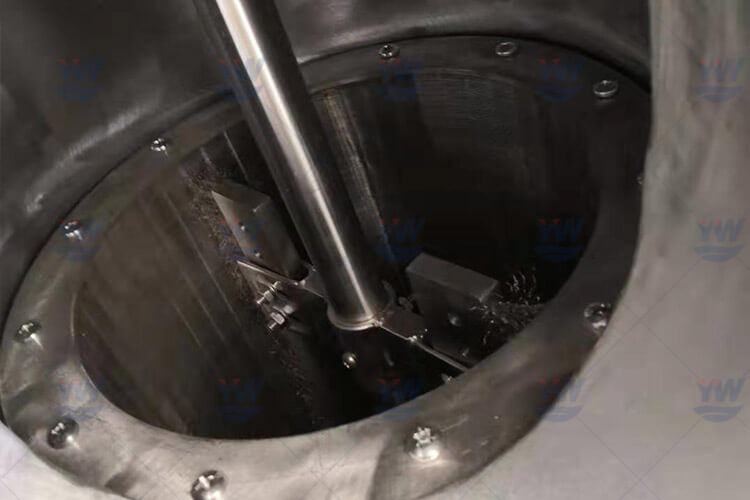

The liquid enters the filter from the water inlet, the impurities in the material are filtered out through the filter screen, and then intercepted to the inner wall of the filter screen, and the filtered liquid is discharged from the outlet.

During the filtration process, the impurities in the inner layer of the filter screen gradually accumulate. When the sewage discharge condition is reached, the brush motor and the sewage outlet valve are automatically opened, and the accumulated impurities are cleaned by the brush and then discharged from the sewage outlet.

Discharge Condition

During the filtration process, the impurities in the inner layer of the filter screen gradually accumulate. When the sewage discharge condition is reached, the brush motor and the sewage outlet valve are automatically opened, and the accumulated impurities are cleaned by the brush and then discharged from the sewage outlet.

Filters with various pressure ranges can be designed and produced according to user needs; filters with temperatures up to 95C are produced through special processes. For filters that need to work in cold conditions, a special filtration control system will be used; for seawater corrosion Special materials such as nickel and titanium alloys are selected, and the filter is specially processed; according to the specific working conditions and requirements of users, targeted solutions can be provided.