Material: Stainless Steel

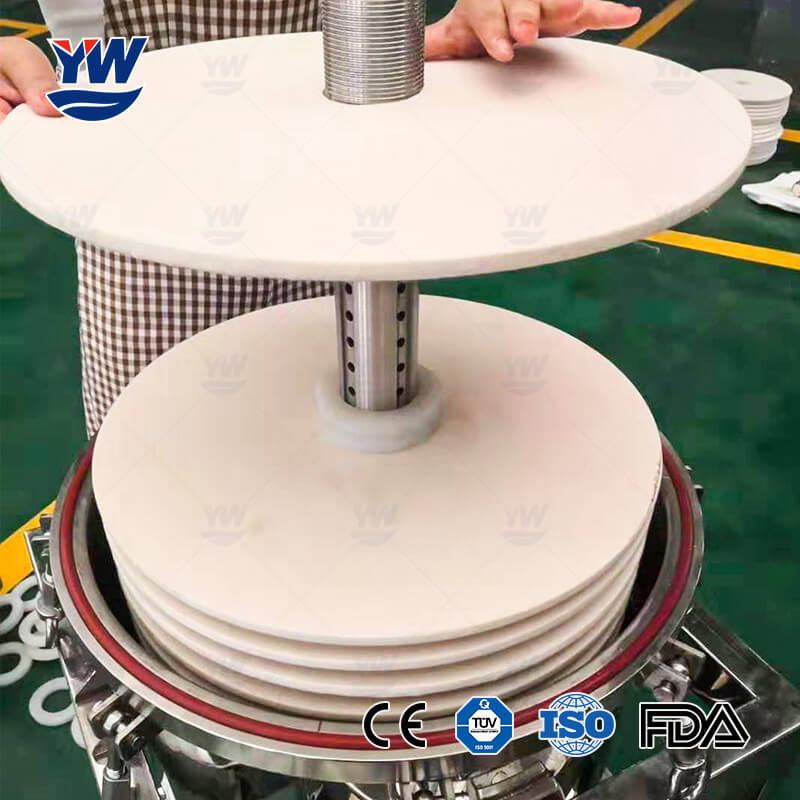

Filter element : Diatomite earth

Filtration area :1-9.6(m²)

Max Flow : 1-20(m³/h)

Diatomaceous earth filter is a filtration equipment that uses diatomaceous earth as a filter aid. Diatomaceous earth as filter aid, suitable for all kinds of liquor, food, beverage liquid filtration.

Yuwei using new technolo¬gy, new technology to manufacture a new YWLS vertical diatomaceous earth filter, stainless steel filter machine has been used in yellow rice wine, brewing and bonding strong liquid drinks, and the use of remarkable effect.

The device is built entirely of 18-10 stainless steel (AISI 304) with filter discs in stainless steel Reps fabric; electric pump, stainless steel pipes and valves, diaphragm pump for dosing diatomaceous earth, recovery of the residual liquid through the last filter disc, quick and easy cleaning of the filter pack, without disassembling the pipes.

| Model | NO. of filter plates | Filtering Area | Inlet | Flow | Work pressure | Power | Dimensions |

| YWLS-1 | 20pcs | 1m² | DN25 | 1-2(t/h) | ≥0.3Mpa | 0.55Kw | 100×300×600(mm) |

| YWLS-3 | 40pcs | 2m² | DN25 | 2-3(t/h) | ≥0.3Mpa | 0.55Kw | 100×300×950(mm) |

| YWLS-5 | 20pcs | 2.4m² | DN32 | 3-5(t/h) | ≥0.3Mpa | 0.75Kw | 1200×600×1350(mm) |

| YWLS-10 | 40pcs | 4.8m² | DN40 | 8-10(t/h) | ≥0.3Mpa | 2.4Kw | 1200×600×1650(mm) |

| YWLS-15 | 60pcs | 7.2m² | DN50 | 12-15(t/h) | ≥0.3Mpa | 3Kw | 1200×600×1800(mm) |

| YWLS-20 | 80pcs | 9.6m² | DN50 | 18-20(t/h) | ≥0.3Mpa | 4Kw | 1200×600×2100(mm) |