1. Preparation before filtration

- Cardboard(filter sheets, filer paper, filter pads) installation should pay attention to distinguish the inflow surface and outflow surface of beer, The rough surface of the cardboard is the inflow surface, and it should be installed when the cardboard is fully wetted with water. It is recommended to sterilize the new cardboard before the first use, the washing time is not less than 15 minutes, and the flow rate is 1.5-2 times of the normal filtration rate. The purpose is to fully infiltrate the cardboard and expand it moderately, remove the air in the cardboard, and achieve a good adsorption effect. In order to prevent wine from leaking when the filter cardboard is installed, check whether the filter rubber ring is intact, and replace it in time if it is damaged.

- In order to prevent damage to the cardboard, check whether there is misalignment between the filter frame and the filter plate and whether there is a protruding part on the sieve plate on the filter frame. If so, use it after repairing.

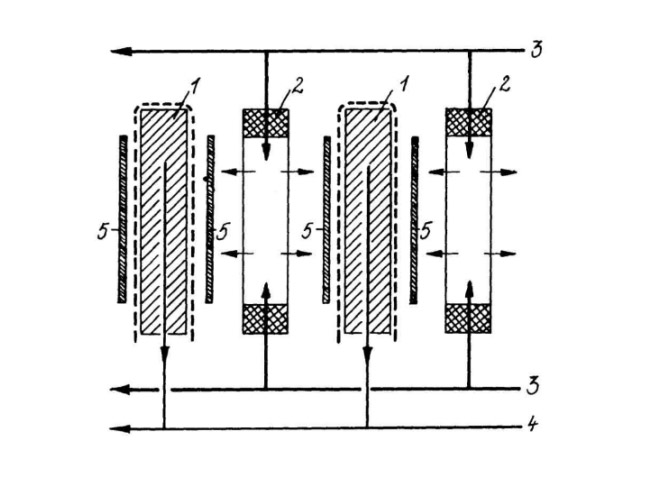

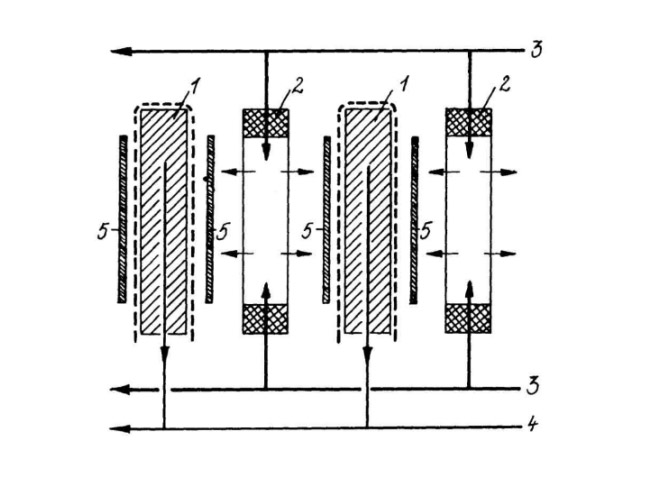

Plate and Frame Filter Filtration Principle

- A support plate with a filter plate hanging

- Filter frame

- Unfiltered liquid inlet

- Filtered liquid inlet

- Diatomaceous earth coating

2. Pre-coating, Adding, Filtering

- Pre-coating: carry out pre-coating according to two pre-coating methods, pre-coating is to deposit a layer of earth on the cardboard to form a basic filter bed by circulating diatomaceous earth slurry, so as to facilitate the clarity of the filtrate. Through the pre-coating process it can prevent the cardboard space from being blocked by viscous substances such as yeast in the filtrate (alcohol), prolong the service life, and also facilitate the cleaning of the cardboard after filtration.

- Adding, filtering:

According to the performance of the filter, the quality of diatomite (activated carbon) and the condition of the filtrate (filtered liquid, fermentation period, yeast content, etc. ), reasonably adjust the proportion and amount of diatomite added, and reasonably adjust the filtration rate to achieve the best filtration effect.

3. Rinse

Rinse, regenerate and sterilize the cardboard after filtration. Carefully rinse the diatomite layer containing yeast, protein and other entrapped substances on the filter cardboard with soft water after each filtration. The washing and filtration are in the same direction. Hot water heated to 85 degrees Pass through the filter cardboard at a normal speed, so that all parts of the filter reach this temperature and keep it for 30 minutes. When sterilizing, check whether there are fibers falling off through the sight glass. The cardboard should be washed and sterilized as soon as possible after the filtration to avoid microbial reproduction. Next time, each filter plate can be used repeatedly 15-20 times under normal conditions.

Basic steps: Pre-coating > Filtering > Draining > Cleaning > Sterilization

Precoating Technology:

Reasons for pre-coating: to form a bridging effect (coarse earth), easy to discharge earth after filtration, and to make the wine liquid that first enters the filter have a preset effective filter layer. (fine earth)

How to precoat:

- Pre-coating solution:

- Selection: tap water, sterile water, beer

- Mixing ratio: 1 : [5~10 (actually 6~8)]

- The first pre-coating is very critical. Although it does not function as a filter, it acts as a support. The amount of coarse earth for this pre-coating is 0.7 ~0.8kg/m, which is about 70% of the entire pre-coating amount.

- The second pre-coating, its function is to clear the first filtered liquor.

- The prerequisite for good pre-coating: The entire filter system is completely exhausted before pre-coating.

- Quality requirements for pre-coating : Consistent thickness, uniform distribution of thickness and fine earth, no bare spots, pre-coating ▲ p = 0.2 ~ 0.3bar