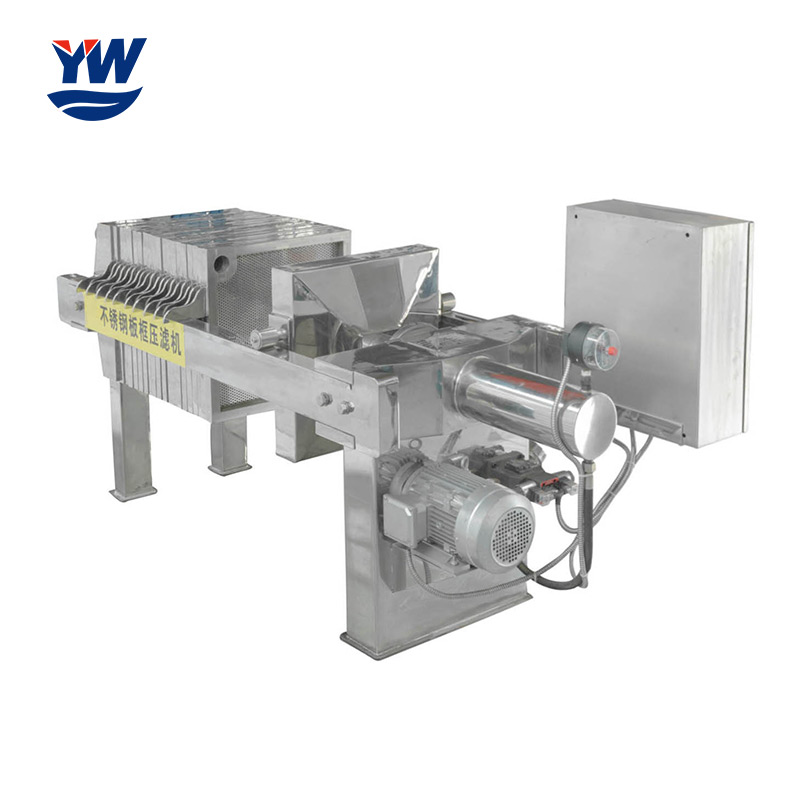

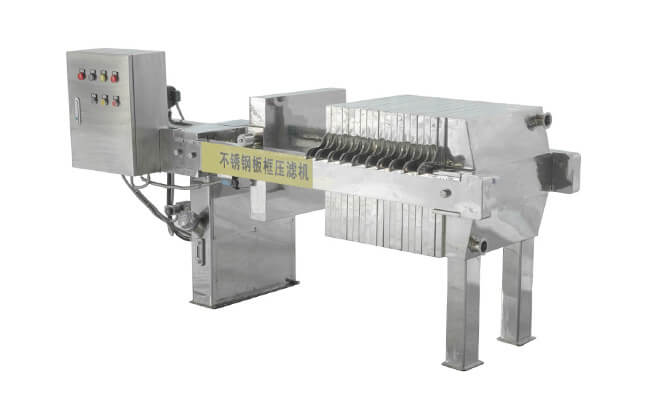

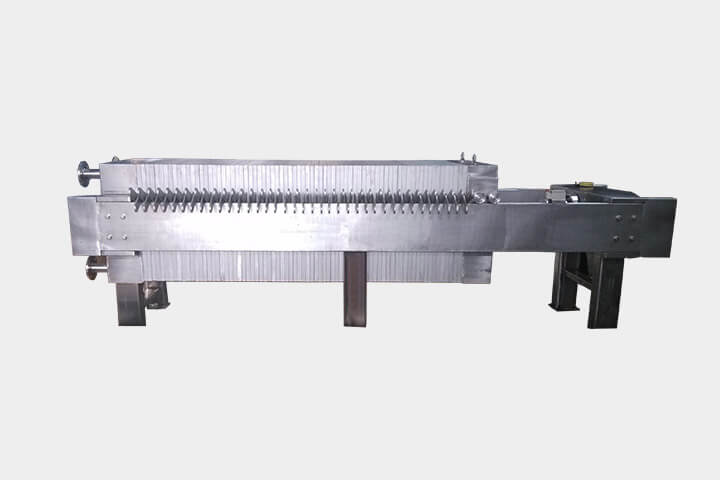

Models : SS Filter Press

Material : 304/316L

Beam : SS304/316

Voltage : 220-380V

Plate Shiting : Manual

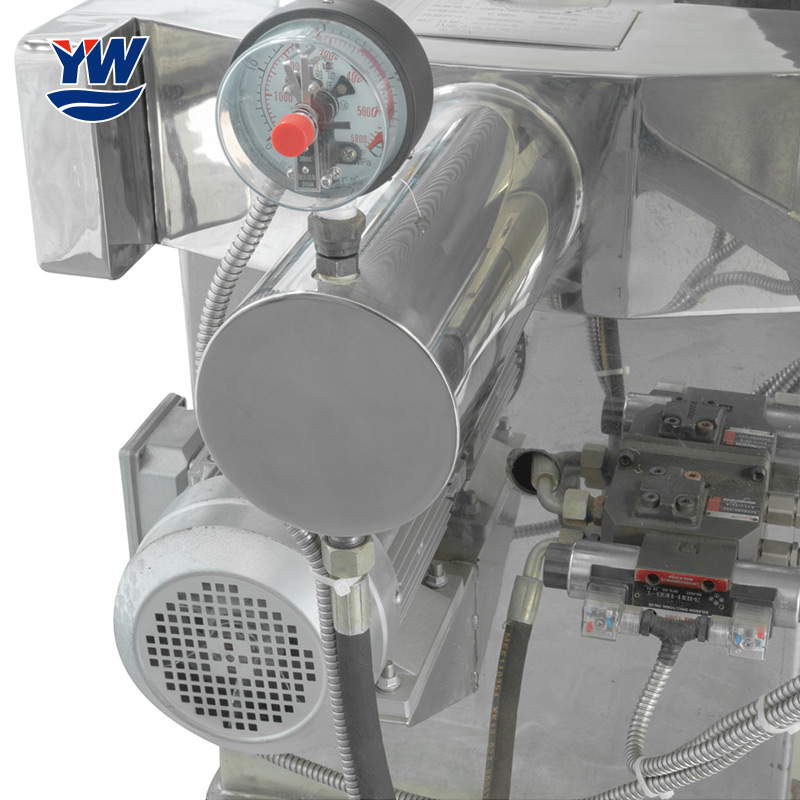

Control : PLC

Feeding Pressure : 0.6Mpa

Plate and frame filter press is a kind of solid-liquid separation equipment, composed of filter plate and filter frame arrangement filter chamber, which is under the pressure of the feed pump.The material is sent to the filter chamber, and then rely on the pressure device to press the filter plate, through the filter cloth to achieve the purpose of separating solid particles and liquid particles. The plate and frame filter press includes three forms which is manual, mechanical and hydraulic pressing.

| Model | Filter area (m²) |

Plate size (mm) |

Filter chamber volume (L) |

Plate Qty. (Pcs) |

Frame Qty. (Pcs) |

Weight (kg) |

Dimensions L*W*H (mm) |

| BAQ1/320 | 1 | 320*320 | 13 | 4 | 5 | 300 | 1050*700*680 |

| BAQ2/320 | 2 | 25 | 9 | 10 | 440 | 1405*700*680 | |

| BAQ3/320 | 3 | 38 | 14 | 15 | 600 | 1650*700*680 | |

| BAQ4/450 | 4 | 450*450 | 51 | 9 | 10 | 780 | 1680*880*900 |

| BAQ6/450 | 6 | 76 | 14 | 15 | 995 | 1980*880*900 | |

| BAQ8/450 | 8 | 102 | 19 | 20 | 1250 | 2180*880*900 | |

| BAQ10/450 | 10 | 122 | 24 | 25 | 1470 | 2430*880*900 | |

| BAQ12/450 | 12 | 152 | 29 | 30 | 1700 | 2680*880*900 | |

| BAQ16/450 | 16 | 203 | 39 | 40 | 2170 | 3180*880*900 | |

| BAY4/450 | 4 | 51 | 9 | 10 | 850 | 2030*880*900 | |

| BAY6/450 | 6 | 76 | 14 | 15 | 1070 | 2280*880*900 | |

| BAY8/450 | 8 | 102 | 19 | 20 | 1950 | 2530*880*900 | |

| BAY10/450 | 10 | 122 | 24 | 25 | 2170 | 2780*880*900 | |

| BAY12/450 | 12 | 152 | 29 | 30 | 2400 | 3030*880*900 | |

| BAY16/450 | 16 | 203 | 39 | 40 | 2870 | 3530*880*900 | |

| BAQ10/610 | 10 | 550*550 | 122 | 15 | 16 | 2030 | 2180*950*1010 |

| BAQ12/610 | 12 | 152 | 19 | 20 | 2290 | 2380*950*1010 | |

| BAQ15/610 | 15 | 189 | 24 | 25 | 2610 | 2630*950*1010 | |

| BAQ20/610 | 20 | 250 | 32 | 33 | 3120 | 3030*950*1010 | |

| BAY10/610 | 10 | 122 | 15 | 16 | 2730 | 2230*950*1010 | |

| BAY12/610 | 12 | 152 | 19 | 20 | 2990 | 2430*950*1010 | |

| BAY15/610 | 15 | 189 | 24 | 25 | 3310 | 2680*950*1010 | |

| BAY20/610 | 20 | 250 | 32 | 33 | 3820 | 3080*950*1010 | |

| BAQ15/630 | 15 | 630*630 | 189 | 18 | 19 | 2620 | 2325*950*1010 |

| BAQ20/630 | 20 | 250 | 24 | 25 | 3100 | 2630*950*1010 | |

| BAQ30/630 | 30 | 377 | 37 | 38 | 4130 | 3280*950*1010 | |

| BAY15/630 | 15 | 189 | 18 | 19 | 2870 | 2630*950*1010 | |

| BAY20/630 | 20 | 250 | 24 | 25 | 3950 | 2930*950*1010 | |

| BAY30/630 | 30 | 377 | 37 | 38 | 4980 | 3580*950*1010 | |

| BAY30/800 | 30 | 725*725 | 442 | 22 | 23 | 5710 | 3150*1300*1300 |

| BAY40/800 | 40 | 595 | 30 | 31 | 7126 | 3630*1300*1300 | |

| BAY50/800 | 50 | 748 | 38 | 39 | 8543 | 4110*1300*1300 |

BAY50/1000

BAY20/800

BAY10/450

BAY30/800(PP Plates)

Fuselage

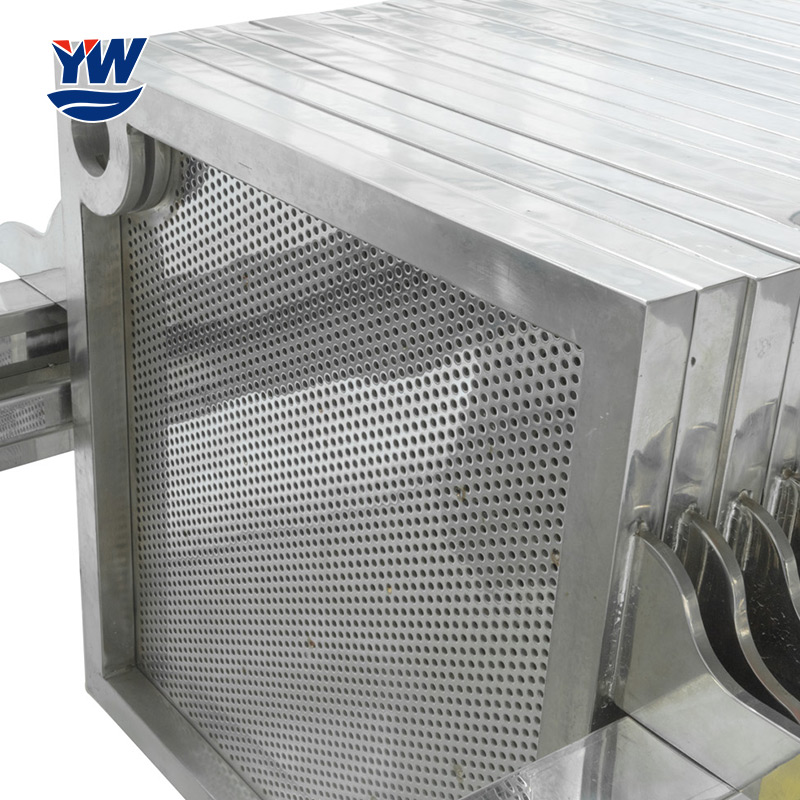

Plate and Frame

Plate frame filter press is composed of filter frame, filter plate and filter cloth. Plate and frame interphase arrangement is the filter chamber; The press cloth is overlaid on the filter plate; The pressure device is used to press the plate and the frame, that is, the filter chamber is formed between the plate and the frame. The plates and frames are made of cast iron, cast steel, stainless steel, polypropylene and rubber.

The plate and frame filter press firstly presses the plate frame group by hydraulic pressure, and the precipitated silt enters from the middle and is distributed among the press cloth. Due to the tight pressure of the plate frame, the silt cannot overflow. Under the high pressure of the screw pump and diaphragm pump, the water in the silt oozes out from the press cloth and flows into the return pipe, while the filter cake stays in the cavity. After the pressure relief of the plate frame, the filter plate is pulled apart, and the filter cake falls down by gravity. Therefore, the pressure filtration process is the last procedure in MP process of sewage treatment.

Plate and frame filter press is widely used in urban sewage treatment, food processing, petrochemical, metallurgical manufacturing, mining, metal forging, pharmaceutical, electronic industry, chemical industry and other industries