Material: Stainless Steel

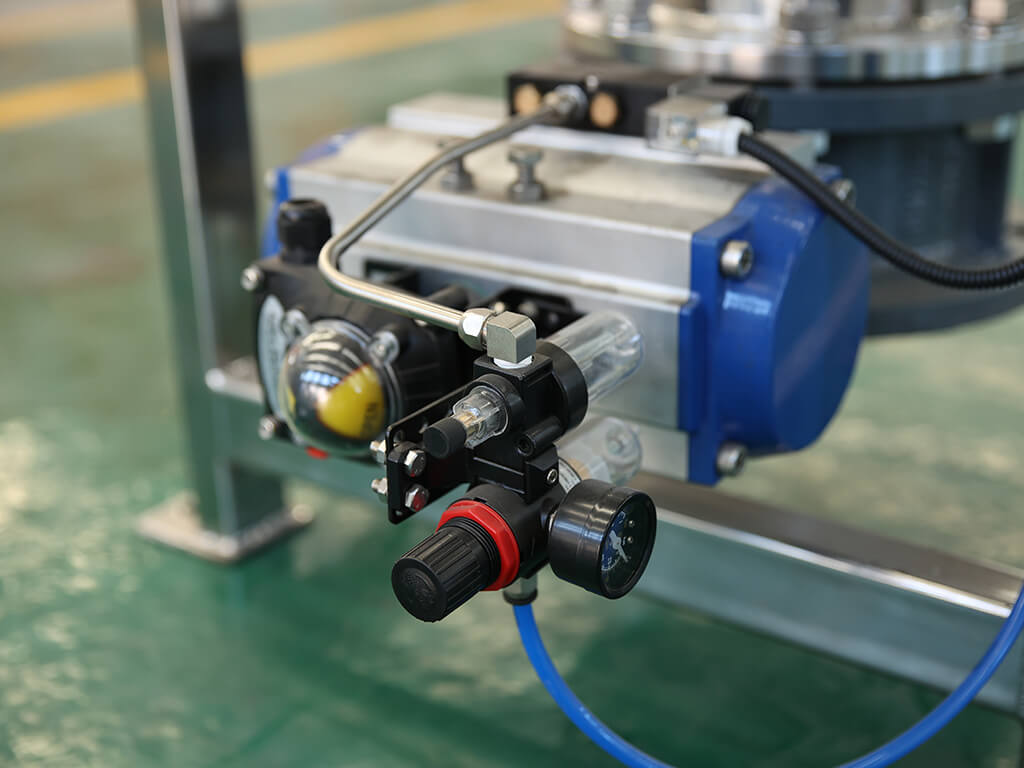

Control: PLC Control

Filter precision : 10-200(μm)

Filter Area : 2-200(m2)

Max Flow : 1-800(t/h)

Working Pressure : 0.1-0.4(Mpa)

The pressure leaf filter, also known as the leaf filter, is a high-efficiency, energy-saving, closed-operation precision clarification and filtration equipment. The product has a unique design structure, high filtration efficiency, and good filtrate transparency and clarity. No filter paper, filter cloth or filter element is consumed, only a small amount of filter aid is consumed, the filtration cost is low, and the equipment is easy to operate and maintain. The equipment can be customized for manual slag discharge and automatic slag discharge, and the filtering area ranges from 2 square meters to 100 square meters. According to the process requirements of filtration, the airtight container has two materials of carbon steel and stainless steel for users to choose.

Remove the slag by vibration to reduce the labor intensity of workers.

| Model | Filter cake volume | Processing power | Workpressure | Filtering cylinder volume | I/O Connection | Discharging outlet | Filter spacing | Weight | ||

| Grease | Resin | Drinks | ||||||||

| YWBL-2 | 30L | 0.4-0.6(t/h) | 1-1.5(t/h) | 1-2(t/h) | 0.1-0.4(Mpa) | 120L | DN25 | DN100 | 50mm | 150Kg |

| YWBL-4 | 60L | 0.8-1.2(t/h) | 2-3(t/h) | 2-4(t/h) | 250L | DN40 | DN125 | 50mm | 180Kg | |

| YWBL-7 | 105L | 1.4-2(t/h) | 3-5(t/h) | 4-8(t/h) | 420L | DN40 | DN150 | 50mm | 326Kg | |

| YWBL-10 | 150L | 2-3(t/h) | 5-8(t/h) | 5-10(t/h) | 890L | DN50 | DN200 | 70mm | 474Kg | |

| YWBL-12 | 240L | 2.4-3.6(t/h) | 6-9(t/h) | 6-12(t/h) | 1190L | DN50 | DN250 | 70mm | 554Kg | |

| YWBL-15 | 300L | 3-5(t/h) | 7-12(t/h) | 8-16(t/h) | 1580L | DN50 | DN250 | 70mm | 815Kg | |

| YWBL-20 | 400L | 4-6(t/h) | 10-15(t/h) | 10-20(t/h) | 1770L | DN65 | DN250 | 70mm | 910Kg | |

| YWBL-25 | 500L | 5-7(t/h) | 12-18(t/h) | 12-24(t/h) | 2200L | DN65 | DN300 | 70mm | 1024Kg | |

| YWBL-30 | 600L | 6-9(t/h) | 14-22(t/h) | 15-30(t/h) | 2770L | DN65 | DN300 | 70mm | 1165Kg | |

| YWBL-36 | 720L | 7-10(t/h) | 16-24(t/h) | 18-36(t/h) | 2870L | DN80 | DN300 | 70mm | 1202Kg | |

| YWBL-40 | 800L | 8-12(t/h) | 20-30(t/h) | 20-40(t/h) | 3500L | DN80 | DN350 | 70mm | 1342Kg | |

| YWBL-45 | 900L | 9-13(t/h) | 22-32(t/h) | 22-44(t/h) | 3630L | DN100 | DN350 | 70mm | 1422Kg | |

| YWBL-52 | 1040L | 10-15(t/h) | 25-40(t/h) | 26-52(t/h) | 4380L | DN100 | DN350 | 75mm | 1900Kg | |

| YWBL-60 | 1200L | 12-18(t/h) | 38-42(t/h) | 30-60(t/h) | 5100L | DN100 | DN400 | 75mm | 2114Kg | |

| YWBL-70 | 1400L | 14-20(t/h) | 35-50(t/h) | 35-70(t/h) | 6940L | DN125 | DN400 | 80mm | 2662Kg | |

| YWBL-80 | 1600L | 16-24(t/h) | 40-60(t/h) | 40-80(t/h) | 8300L | DN125 | DN400 | 80mm | 3882Kg | |

The closed plate filter is mainly composed of a complete filtering system consisting of a filter host, a delivery pump, pipelines, valves and other auxiliary equipment. The filter host is composed of filter tank, filter screen, cover lifting mechanism, automatic slag removal device, etc.