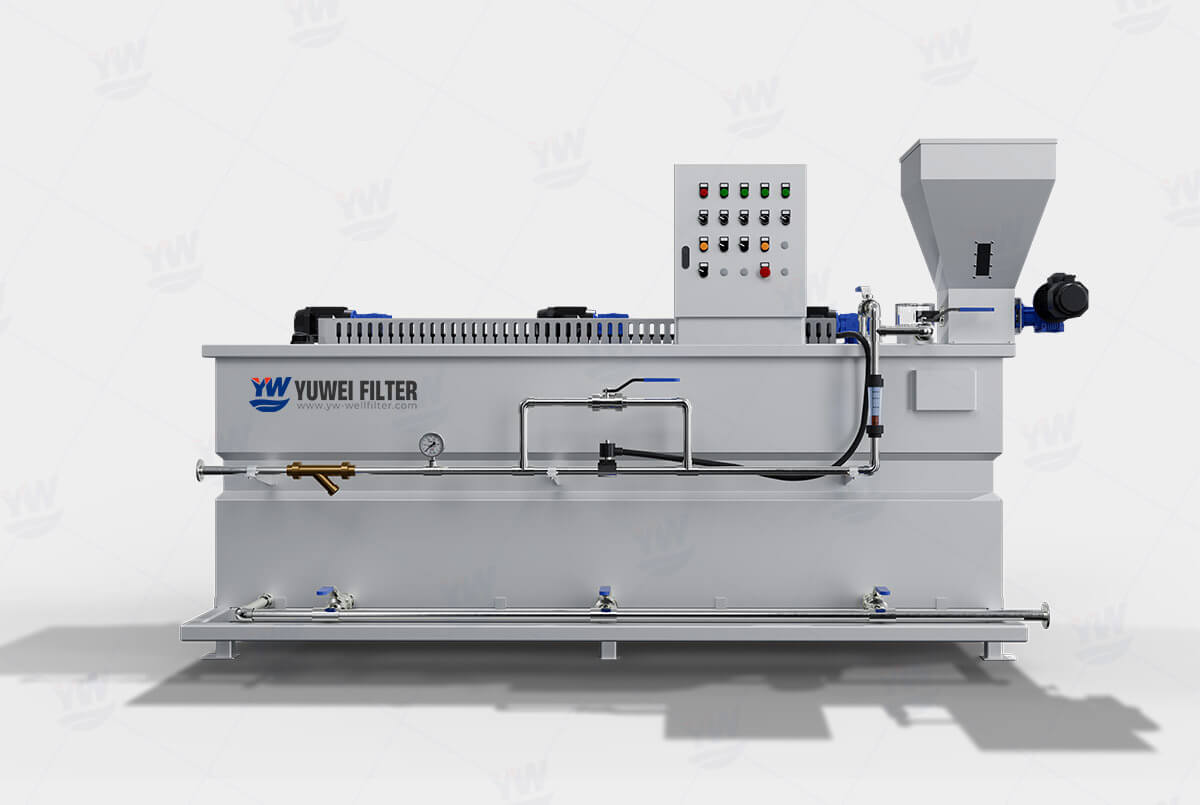

Models : Belt filter press

Type : Three filter belt type concentrated filter press

Filter Area : 3-45m³/hr

Dry Solid : 45-675kg/hr

Cake Moisture : 65%-84%

The concentration integrated belt filter press is an industrial machine used for sludge thickening and dewatering. This product is suitable for treating all kinds of sludge in municipal sewage treatment, chemical industry, textile, printing and dyeing, papermaking, leather, pharmaceutical, brewing, feedlot and other industries.

The machine adopts stainless steel material, corrosion resistance, wide applicability and long service life.

| Model | Belt Width | Low Consistency | Middle Consistency | Power | Dimensions (L*W*H) |

Weight | ||||

| Capacity [ Feed Concentration (Solid content 0.5%-1%) ] |

Dry Solid | Capacity [ Feed Concentration (Solid content 1%-1.5%) ] |

Dry Solid | Driving Motor | Mixing Power | Gravity concentrator motor |

||||

| DNY500-3 | 500mm | 7.5-10(m³/hr) | 30-60(kg/hr) | 6-7.5(m³/hr) | 50-94(kg/hr) | 0.75kw | 0.75kw | 0.55kw | 2600*1050*2175(mm) | 1200kgs |

| DNY750-3 | 750mm | 10.5-15(m³/hr) | 42-90(kg/hr) | 9.3-10.5(m³/hr) | 75-140(kg/hr) | 0.75kw | 0.75kw | 0.55kw | 2600*1300*2160(mm) | 1600kgs |

| DNY1000-3 | 1000mm | 15-20(m³/hr) | 60-120(kg/hr) | 12.5-15(m³/hr) | 100-188(kg/hr) | 0.75kw | 0.75kw | 0.55kw | 3000*1550*2160(mm) | 1800kgs |

| DNY1250-3 | 1250mm | 21-25(m³/hr) | 84-168(kg/hr) | 17.5-21(m³/hr) | 140-263(kg/hr) | 0.75kw | 0.75kw | 0.55kw | 3000*1800*2160(mm) | 1960kgs |

| DNY1500-3 | 1500mm | 25-30(m³/hr) | 100-198(kg/hr) | 20-25(m³/hr) | 160-300(kg/hr) | 0.75kw | 0.75kw | 0.55kw | 3000*2050*2160(mm) | 2250kgs |

| DNY1500L-3 | 1500mm | 28-35(m³/hr) | 110-215(kg/hr) | 22-28(m³/hr) | 1680-330(kg/hr) | 0.75kw | 0.75kw | 0.55kw | 3000*2500*2160(mm) | 2600kgs |

| DNY1750-3 | 1750mm | 30-40(m³/hr) | 120-234(kg/hr) | 24-30(m³/hr) | 196-368(kg/hr) | 0.75kw | 0.75kw | 0.55kw | 3000*2300*2160(mm) | 2800kgs |

| DNY2000-3 | 2000mm | 35-45(m³/hr) | 140-270(kg/hr) | 28-35(m³/hr) | 240-450(kg/hr) | 1.1kw | 0.75kw | 0.55kw | 3200*2550*2180(mm) | 3200kgs |

| DNY2500-3 | 2500mm | 40-45(m³/hr) | 180-350(kg/hr) | 35-50(m³/hr) | 300-550(kg/hr) | 2.2kw | 1.5kw | 0.75kw | 4600*3050*2600(mm) | 3600kgs |

| DNY3000-3 | 3000mm | 50-65(m³/hr) | 220-420(kg/hr) | 45-60(m³/hr) | 650-650(kg/hr) | 3kw | 2.2kw | 1.5kw | 4600*3550*2600(mm) | 4000kgs |

Sludge concentration entering the drum belt dewatering equipment integration, Preparation through flocculant dosing system will be mixed into the polymer flocculant reaction vessel.

In the mixing reaction vessel, sludge and polymer flocculant mixed by stirring, Fine particles of sludge from the rapid rally agglomerate to bigger particles, and reticular formation and structure of the big corporations floc, then enter the expected slow rotating drum which dehydration. The sludge was transported to a special device drum ends of the process, most of the free water was released through the filter cloth, Concentrated achieve results, the effluent from the filter and the collection tank sludge and solid separation.

After the pre-dewatering sludge from the ramp slip back belt press filter onto the upper, then the lower part of the transmission belt filter. In the upper and lower bands filter, and gradually boosting the role of shear stress, sludge dewatering further after discharge.

Sludge production and stem degrees can be limitless speed control device to clean water supplied from Level Control Systems.