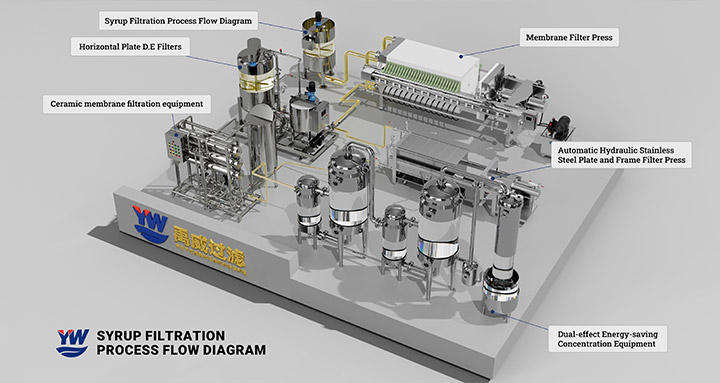

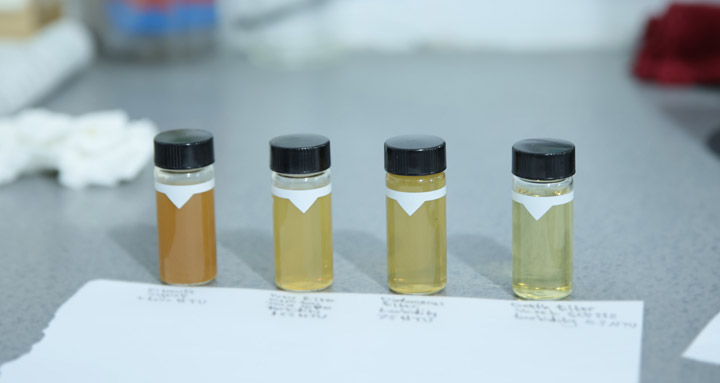

The filtration process of sugar syrup is a core step in sugar production, aimed at removing impurities, suspended solids, pigments, and microorganisms from the syrup to ensure its purity, clarity, and stability. Through scientific filtration process design and strict procedural control, the transparency, stability, and safety of the syrup are enhanced, meeting the high-standard requirements of industries such as food and pharmaceuticals.

Sugar Syrup Filtration

Sugar Syrup Filtration

| Syrup Type | Filtration Challenges | Process Optimization Solutions |

| Cane Syrup | High colloid & pigment content | Activated carbon adsorption + ultrafiltration decolorization |

| Starch Syrup | Prone to gelatinization, high viscosity | Low-temperature dilution + diatomaceous earth pre-filtration |

| Fruit Syrup | Pectin & fine fruit pulp fibers | Pectinase pretreatment + centrifugal separation |

| Sugar-free Syrup (e.g., Erythritol) | Filter media clogging by crystals | Heating & dissolution + precision filter cartridge interception |