Models : Stainless Steel Filter Press

Filter Area : 1-50m²

Filter volume : 13-748L

Press system : Hydraulic / Manual Jack

Feeding Pressure : Hydraulic / Manual Jack

Round Plate Stainless Steel Filter Press are developed specifically to meet the high requirements of hygiene and purity. Due to its high standard of hygienic application, these can be used for separation of plasma, harvesting of proteins, clarification of filtered vaccines and antibiotics.

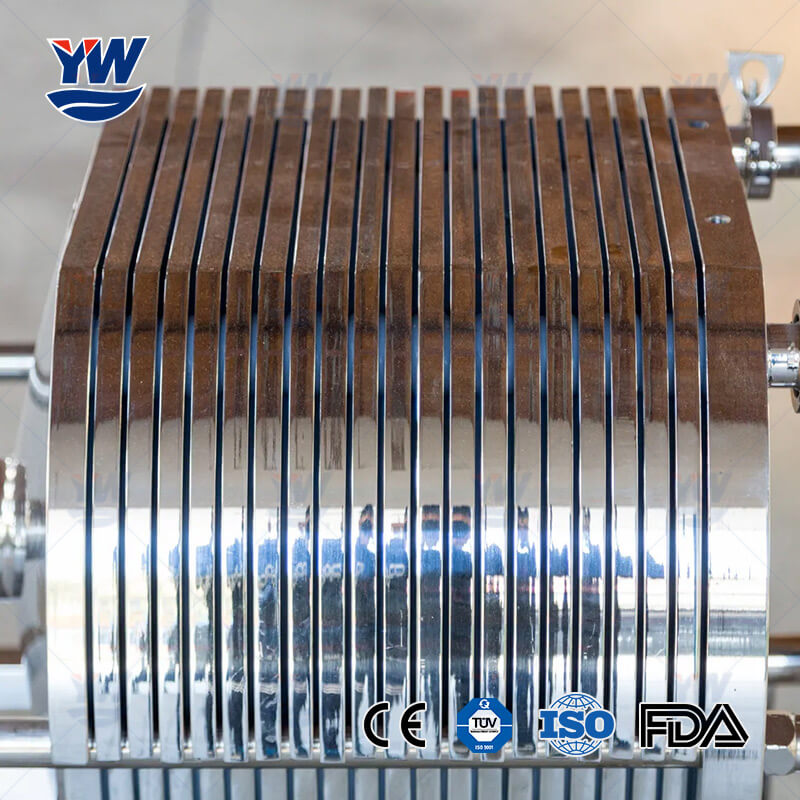

The whole Round Plate Stainless Steel Filter Press is made of 1Cr18Ni9Ti or 304, 306 high quality stainless steel material. Polishing surface, filter cloth or membrane filtering, sealing and stainless steel pump. The filtration temperature can reach above 200°C. Especially for solid-liquid seperation of lab usage, fine chemical, pharmaceutical, herbal extraction, food,cosmetics production.

Using precision sterilization cardboard can filter all kinds of health care wine, wine, can achieve sterilization effect. Yuwei can also provide customers with special food grade filter cloth and food grade filter plate package, professional choice for customers' applications.

When it is necessary to filter some viscous materials with a lower concentration or some closed filtration of liquid with low slag content, it is used for purification, clarification, sterilization and so on fine filtration, semi-fine filtration. The purpose of aseptic purification and filtration can be achieved by using microporous filter directly. Plate and frame filter press with microporous filter membrane is currently a good equipment to solve the chemical industry, pharmaceutical food and other industries to filter activated carbon, particles, etc., to ensure no activated carbon powder flow out.

Plate

Frame

| Model | Layer NO. | Filter area (m²) |

Plate size (mm) |

Fiter precision (um) |

Filtration pressure (MPa) |

Flow rate (t/h) |

Feeding Pump power (KW) |

Dimension (mm) |

| YWDC-100 | 10 | 0.078 | φ100 | 0.22-100 | 0.3 | 0.8 | 0.37 | 600*300*600 |

| YWDC-150 | 10 | 0.17 | φ15O | 0.22-100 | 0.3 | 1.5 | 0.55 | 650*380*650 |

| YWDC-200 | 10 | 0.34 | φ2OO | 0.22-100 | 0.3 | 2 | 0.75 | 650*400*700 |

| YWDC-300 | 10 | 0.7 | φ300 | 0.22-100 | 0.3 | 4 | 0.75 | 700*500*800 |

| YWDC-400 | 10 | 1.25 | φ4OO | 0.22-100 | 0.3 | 6 | 1.1 | 900*600*1000 |

| YWDC-400 | 16 | 2 | φ4OO | 0.22-100 | 0.3 | 9 | 1.5 | 1000*600*1000 |

| YWDC-400 | 20 | 2.5 | φ400 | 0.22-100 | 0.3 | 10 | 1.5 | 1100*600*1000 |

| YWDC-400 | 32 | 4 | φ400 | 0.22-100 | 0.3 | 13 | 1.5 | 1320*600*1000 |

| YWDC-200 | 10 | 0.4 | 200x200 | 0.22-100 | 0.3 | 3 | 0.55 | 650*380*650 |

| YWDC-300 | 10 | 0.9 | 300x300 | 0.22-100 | 0.3 | 6 | 0.75 | 700*500*800 |

| YWDC-400 | 10 | 2 | 400x400 | 0.22-100 | 0.3 | 10 | 1.1 | 900*600*1000 |

| YWDC-400 | 20 | 3 | 400x400 | 0.22-100 | 0.3 | 12 | 1.1 | 1100*600*1000 |

| YWDC-400 | 26 | 4 | 400x400 | 0.22-100 | 0.3 | 15 | 1.1 | 1150*600*1000 |

| YWDC-400 | 32 | 5 | 400x400 | 0.22-100 | 0.3 | 18 | 1.5 | 1200*600*1000 |

| YWDC-400 | 38 | 6 | 400x400 | 0.22-100 | 0.3 | 21 | 1.5 | 1300*600*1000 |

| YWDC-400 | 44 | 7 | 400x400 | 0.22-100 | 0.3 | 23 | 1.5 | 1350*600*1000 |

Filter plate is made of SUS304 or SUS316L pure stainless steel, threaded structure, according to the user's different products to replace different filter materials (filter materials can be microporous filter membrane, filter paper, filter cloth, clarification plate, etc.); The sealing ring adopts silicone and fluorine rubber (acid and alkali resistant) two kinds, no leakage, good sealing performance.

The machine can be optional stainless steel or polypropylene filter plate.

It mainly applies to the medicine industry (pharmaceutical injection, pharmaceutical liquid filtration), food and beverage, chemical industry etc.