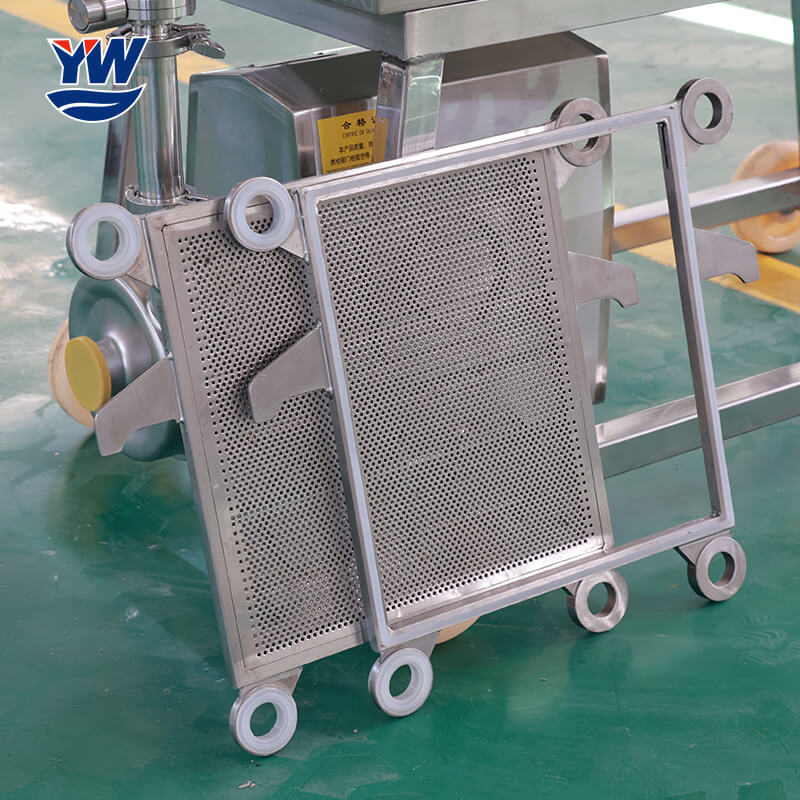

Material: S.S.304 (S.S.316 is selectable)

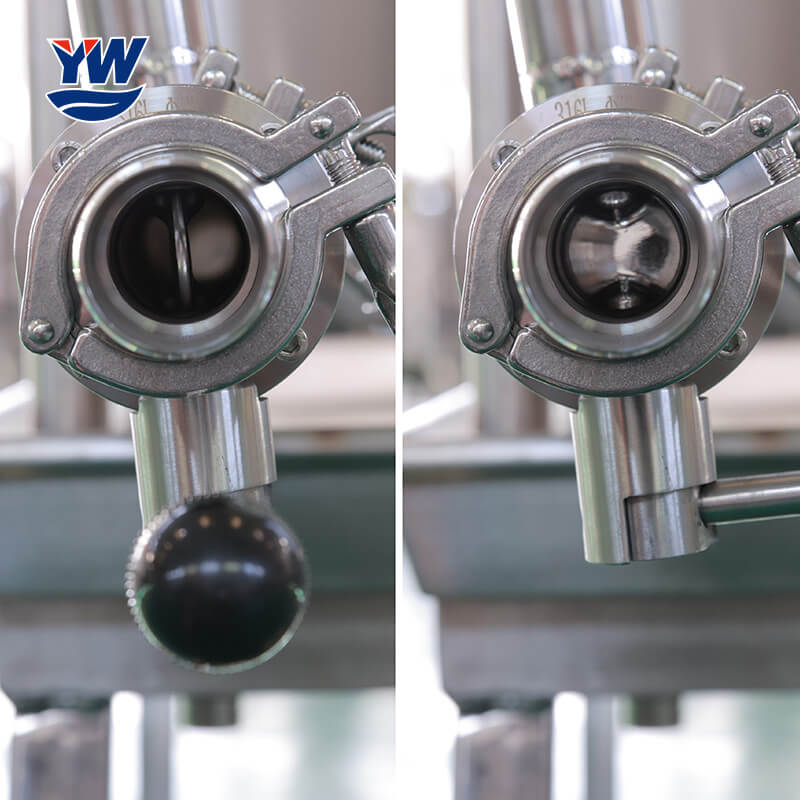

Seal Material : Food Grade Silicone Rubber

Pressure : 0.4 MPa

Temperature : ≤ 120 °C.

Plate Thickness : 13 mm; Individual Chamber Volume: 4.8 L.

Squeezing Method : Screw/Manual Hydraulic (Others: Manual Jack/Automatic Hydraulic etc..)

Filtering Precision : from 200 mesh to 0.22μm.

Stainless steel filter press is a product that integrates coarse filtration and fine filtration, and is suitable for solid-liquid separation of various suspensions. The main condition is to select different filtration mustards according to the user's requirements for the production products, so as to achieve the purpose of decarbonization, clarification and sterilization, and can also be used for slag retention and water removal. It is widely used in medicine, food, chemical industry, environmental protection, water treatment and other industries.

| Model | Filter Area(m²) | Plate Qty | Flow(T/h) | Plate Size(mm) | Dimension(mm) |

| BASJL400-2 | 2 | 15 | 1-2 | 400*400 | 1250*660*1300 |

| BASJL400-3 | 3 | 21 | 1-3 | 400*400 | 1350*660*1300 |

| BASJL400-4 | 4 | 31 | 3-4 | 400*400 | 1550*660*1300 |

| BASJL400-6 | 6 | 45 | 4-6 | 400*400 | 1750*660*1300 |

| BASJL400-8.5 | 8.5 | 61 | 6-8 | 400*400 | 2100*660*1300 |

| BASJL400-9.5 | 9.5 | 71 | 8-10 | 400*400 | 2300*660*1300 |

| BASJL600-14 | 14 | 41 | 10-13 | 600*600 | 1750*870*1350 |

| BASJL600-21 | 21 | 61 | 15-20 | 600*600 | 2100*870*1350 |

| BASJL600-24 | 24 | 71 | 20-25 | 600*600 | 2250*870*1350 |

| BASJL600-35 | 35 | 101 | 25-30 | 600*600 | 2800*870*1350 |

The stainless steel filter press is suitable for closed filtration of liquids with a concentration below 50%, low viscosity and low slag content to achieve the requirements of fine filtration and semi-fine filtration such as purification, sterilization and clarification. Filtration through a microporous membrane filter can achieve the purpose of sterile filtration.

It is widely used in the production of medicinal liquid preparations (traditional medicine extracts and other medicinal filtration), infusion and oral liquids in the pharmaceutical industry; winemaking, fruit juice, beverages, mineral water; soy sauce, vinegar, edible oil, honey, syrup; light industry, liquid clarification and filtration in petroleum, chemical, metallurgy, electronics, environmental protection and other departments.