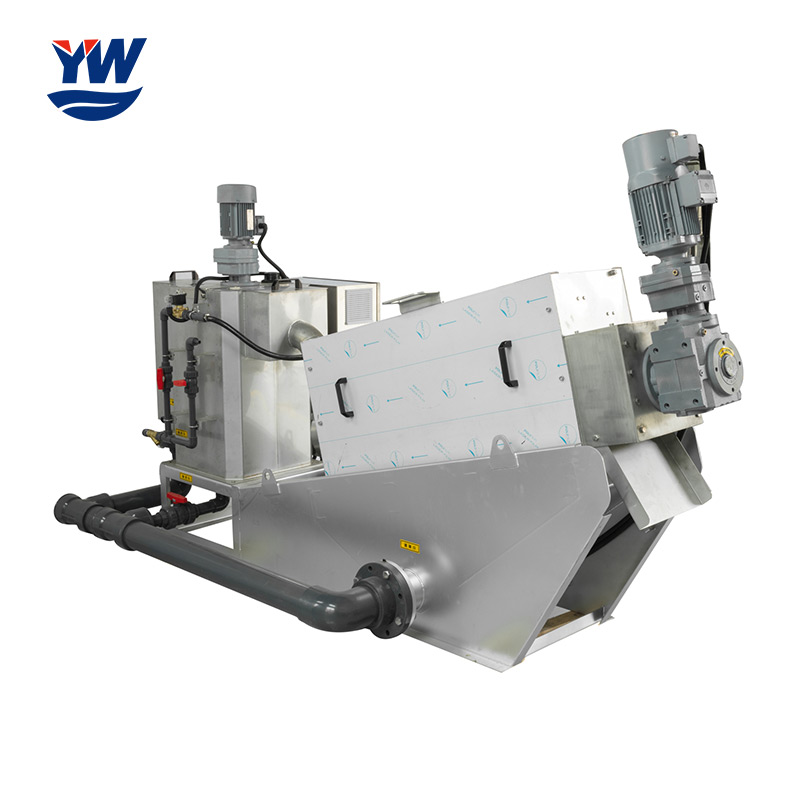

The screw stacking sludge dewatering machine is mainly used for sludge dewatering, and the moisture content of the sludge can be reduced to 75%-85% after dehydration. This machine are integrated fully automatic control cabinet and the liquid collection tank, which can realize high-efficiency flocculation under the condition of fully automatic operation. It continuously complete the sludge concentration and pressing dehydration work, and which finally return or discharge the collected filtrate。

The recommended sludge concentration is between 2000mg/L and 5000mg/L.

Equipped with a proprietary rotary disc pre-concentration device, it is better at dealing with low-concentration sludge, improving the shortcomings of existing gravity concentration, and achieving high-efficiency concentration of low-concentration sludge.

The integration of flocculation and concentration is completed, and the subsequent dehydration pressure is reduced and the expansion valve is adjusted to adjust the sludge concentration to a better dehydration state.

The dynamic fixed ring replaces the filter cloth, self-cleaning, no clogging, easy to deal with oily sludge.

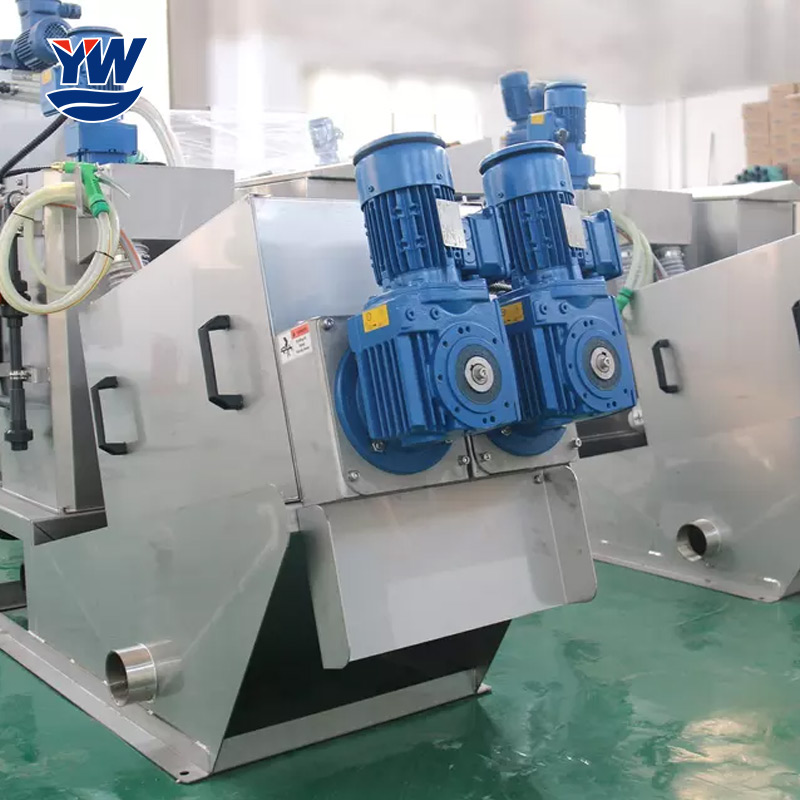

Under the action of the rotation of the screw shaft, the movable plate of the stacked screw sludge dewatering machine is constantly displaced relative to the fixed plate, so as to realize the continuous self-cleaning process and avoid the common clogging problem of the traditional dewatering machine. Therefore, it has strong anti-oil pollution ability, easy separation and no blockage. And it is equipped with high pressure water gun.

Energy saving and emission reduction, reduce noise pollution

The screw type sludge dewatering machine relies on large-scale equipment such as volumetric pressure dewatering and barrel matching to achieve a low operating speed of 2-4 revolutions per minute. Therefore, the machine can achieve low energy consumption, low water consumption, and low noise. The average energy consumption is only 1/8 of the belt machine, 1/20 of the centrifuge, and the unit energy consumption is only 0.01-0.1 kwh/kg-DS, which can reduce the operating cost of the sewage treatment system.

The main body of the stacked screw dehydrator is a filter device formed by stacking a fixed ring and a moving ring, and the screw shaft runs through it. The front section is the concentration section, and the rear section is the dehydration section. The filter gap formed between the fixed ring and the moving ring and the pitch of the screw shaft gradually decrease from the concentration part to the dehydration part. The rotation of the screw shaft pushes the sludge to be transported from the thickening part to the dewatering part, and at the same time drives the swimming ring to clean the filter seam to prevent clogging.

Screw stacking sludge dewatering machine is widely used in municipal sewage treatment projects and water treatment systems in petrochemical, light industry, chemical fiber, paper, pharmaceutical, leather and other industrial industries. It is suitable for dewatering of high and low concentration sludge. When dewatering low-concentration (2000mg/L~) sludge, there is no need to build thickening tanks and storage tanks, which reduces construction costs, reduces the release of phosphorus and the generation of anaerobic odor.